Exploring Chain Making Machines

Chain making machines are sophisticated devices engineered to fabricate a multitude of metal chain types. These machines play a pivotal role in the jewelry industry's manufacturing operations, producing chains for adornments such as necklaces, bracelets, anklets, and waist belts. Beyond jewelry, they are indispensable in sectors like fashion, construction, and industry, where chains function as connectors or fasteners.

A chain making machine operates through several core stages: selecting the appropriate material, shaping, welding, and applying the final touches. The process typically begins with a metal wire spool or coil that is fed into the machine. This wire is straightened, trimmed to the required length, and molded into the designated link shape. For example, the popular curb chain consists of interlocked, angled links that rest flat.

Diverse configurations of chain making machines cater to specific chain varieties and production scales. High-speed machines cater to mass production, while manual or semi-automatic variants are suitable for smaller outputs or bespoke chain designs. These machines must conform to stringent quality controls to ensure the resulting chains possess the requisite durability for their intended applications.

Varieties of Chain Making Machines

To accommodate the jewelry industry's varied demands, chain making machines are available in several iterations, each with unique features tailored to different production requirements:

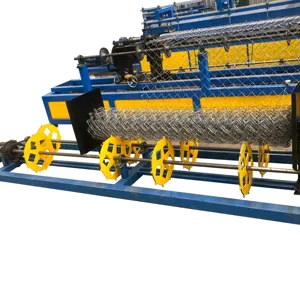

- Automatic Chain Link Fence Machine: This variant is adept at crafting chain link fences with a diamond pattern, handling wire diameters up to 3.0mm, and is typically used for garden enclosures and highway barriers.

- Wire Mesh Welding Machine: Designed for wire mesh production, this machine type can weld wires into a grid configuration, ideal for creating construction materials and road reinforcement meshes.

- Chain Link Weaving Machine: These machines produce the signature chain pattern by interweaving warp and weft wires, commonly used for fashion accessories and home decor chains.

- Automatic Chain Link Fence Making Machine: An enhanced version of the chain link fence machine, it accommodates thicker wires and features automated controls for a fully automated process.

Each machine type fulfills a role in different jewelry market segments, from high-speed stainless steel chain production to delicate weaving for intricate designs.

Selecting the Right Chain Making Machine

Choosing the appropriate chain making machine for your enterprise requires a thorough understanding of your production line's specific needs. Key factors to consider include:

-

Capacity: Assess the quantity of chain production necessary to meet your demands, taking into account both present and potential future needs.

-

Material: The material you intend to use (e.g., carbon steel, stainless steel) will dictate your machine choice, given the variations in hardness and tensile strength.

-

End Product: Determine the chain style you aim to manufacture (such as link or welded chains) and select a machine adept at producing that specific design efficiently.

-

Automation Level: Weigh your labor costs and production targets to decide if a more automated machine (like an automatic chain link fence making machine) would enhance efficiency.

-

Local Service Availability: Confirm the availability of local support for the installation, maintenance, and repair services in your area.

-

After-Sales Service: Opt for suppliers offering comprehensive after-sales services, including online or video technical support, to address any operational challenges.

Chain Making Machines on Alibaba.com

Alibaba.com distinguishes itself as a premier marketplace for sourcing dependable and proficient chain making machines. Its extensive network of suppliers presents a broad spectrum of machines tailored for various production demands, enabling businesses worldwide to procure superior equipment. Alibaba.com is the go-to platform for standard and specialized chain production, offering detailed specifications and supplier insights.

The platform's dedication to promoting international commerce is reflected in features that support local language communication and mobile-friendly purchasing options. Alibaba.com's Trade Assurance service further ensures a secure purchasing experience by safeguarding payments until delivery confirmation, thus reducing the risks associated with global trade.

Alibaba.com's vast selection empowers businesses to not only fulfill their current needs but also to augment their capabilities by accessing cutting-edge technology from leading suppliers in chain making machinery. Leveraging Alibaba.com as your sourcing platform grants your business access to a premier selection that can streamline your operations and bolster your market competitiveness.

Frequently Asked Questions About Chain Making Machines

What is the purpose of a chain making machine?

Chain making machines are primarily employed in the fabrication of metal chains, including roller, link, and decorative chains, serving a vital role across various industries from production to jewelry design and repair.

How does a chain making machine function?

Chain making machines automate the crafting of individual chain links or plates through techniques like forging and welding, which are subsequently assembled into larger chains or interconnected.

What variety of chains can be produced with chain making machines?

Chain making machines are capable of producing an extensive array of chains, such as roller, link, ball, and decorative chains, each designed for particular applications and product requirements.

What considerations are important when selecting a chain making machine for my business?

In selecting a chain making machine, take into account the types of chains to be produced, the specifications required, the machine's production capacity, operational ease, and the availability of after-sales support.

Can chain making machines produce different sizes of chains?

Yes, chain making machines are available that can manufacture chains in various sizes. It is crucial to select a machine that can accommodate the production range you need.

Is it possible to customize chain making machines for specific needs?

Suppliers often provide customization options for chain making machines to cater to particular business requirements, including adjustments to the machine's core components, material specifications, and functionalities.

What materials are commonly utilized in chains made by chain making machines?

Chain making machines frequently produce chains from materials such as stainless steel, carbon steel, alloy steel, and occasionally precious metals, with the choice of material influenced by the desired durability and aesthetic of the end product.

How does a business determine the necessary production capacity from a chain making machine?

A business should consider factors like the machine's design specifications, the type of chain being produced, the material used, and the operational setup to determine the production capacity in line with its goals.

What after-sales services are crucial when purchasing a chain making machine?

Seek suppliers who offer extensive after-sales services, including online support, video technical assistance, engineers for overseas machinery servicing, or field maintenance and repair services.

How can I ensure the chain making machine is compatible with my existing production equipment?

Verify the supplier's specifications and compare them with your current machinery to ensure compatibility with the new chain making machine. Modifications to your existing equipment or additional compatible machinery investments may be necessary.

Are eco-friendly options available among chain making machines?

Certain modern chain making machines incorporate features that reduce energy consumption or utilize sustainable materials in the manufacturing process. Consider these eco-friendly options if environmental impact is a concern for your business.

Why are core components like motors and PLCs important in chain making machines?

Essential components such as motors and PLCs are crucial as they drive the machine's functionality. It is important to ensure these components are of high quality and reliability to reduce technical issues and production downtime.

Can I find a chain making machine that is user-friendly?

Many chain making machines are designed with interfaces and controls that are intuitive to use. Features such as touch screen interfaces or programmable settings can simplify operation and allow for easy customization of machine functions.

What maintenance is required for a chain making machine?

Regular maintenance of a chain making machine typically involves checking lubrication systems, verifying the proper function of safety features, and inspecting for wear and tear on moving parts.

How does Alibaba.com facilitate the search for chain making machine suppliers?

Alibaba.com provides a platform where businesses can filter suppliers based on criteria such as trade assurance status, location, and minimum order quantities, streamlining the search for a suitable supplier.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4