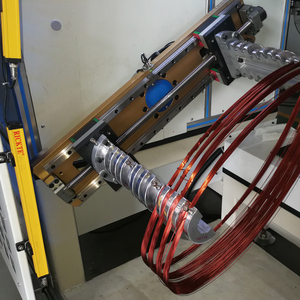

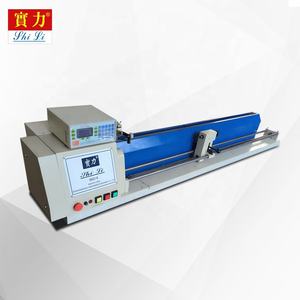

Murata Winder Machine: An Overview

The Murata winder machine stands as a pivotal tool in the realm of electrical motor repairs and manufacturing. Designed to streamline the process of coil rewinding, this machinery is a cornerstone in workshops and factories where efficiency and precision are paramount. The Murata winder is engineered to cater to a variety of coiling tasks, making it a versatile asset in the production of electrical components such as solenoids and transformers.

Types and Applications

There exists a spectrum of Murata winder machines tailored to diverse industrial and commercial needs. From autonomous, fully automated systems that promise consistency and high throughput to semi-automatic and manual options that offer flexibility and adaptability, the range of machines serves a broad array of applications. These winders are not just confined to large-scale operations but are also suitable for smaller, cottage industry settings.

Features and Precision

The hallmark of a Murata winder is its ability to deliver precision. With options for fully automated control, these machines ensure that each coil is wound to exact specifications, thereby enhancing the quality of the final product. The simplicity of operation allows for a single individual to manage the process, which can significantly reduce labor requirements and enhance workflow efficiency.

Materials and Durability

Constructed with robust materials, the Murata winder machine is built to withstand the rigors of continuous industrial use. This durability ensures that the machine remains a reliable component of the production process over time, minimizing the need for frequent maintenance and thus reducing operational downtime.

Advantages of Integration

Incorporating a Murata winder into your production line can lead to a substantial reduction in the time required for coil winding tasks. This efficiency gain not only boosts production capacity but also allows for the reallocation of resources to other areas of production, optimizing overall workflow. Furthermore, the consistent quality of the winding process can enhance the reliability of the finished electrical components.

Selection and Customization

Selecting the right Murata winder machine is crucial, and the vast inventory on Alibaba.com caters to this need by offering machines that meet various commercial and industrial requirements. These machines are designed to comply with international production standards, ensuring that they integrate seamlessly into existing production lines. While the platform facilitates connections between buyers and suppliers, it is also a resource for finding a machine that aligns with specific operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4