Introduction to 5 Ton Soybean Oil Refinery Equipment

The 5 ton soybean oil refinery is a pivotal component in the edible oil industry, designed to refine crude soybean oil into a consumable product. This category encompasses a range of machinery, each tailored to streamline the refining process, ensuring efficiency and consistency in output.

Types of Soybean Oil Refining Machinery

Refining equipment is categorized mainly into hydraulic and screw oil press machines. The hydraulic variant merges traditional extraction techniques with modern technology, applying pressure and heat to extract oil. Conversely, the screw oil press machine relies on a mechanical screw, exerting high pressure to squeeze oil from soybeans.

Applications and Features

A soybean oil refining machine is versatile, serving large-scale oil production lines. Its application extends to producing refined oil that meets industry standards for consumption. Features of this machinery include a robust pressing chamber, high-pressure endurance, and the ability to maintain consistent temperatures, crucial for optimal oil quality.

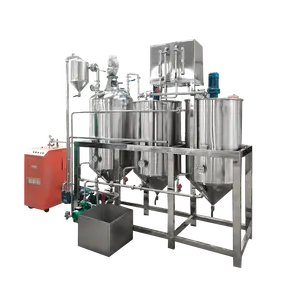

Material and Construction

Constructed to handle substantial volumes, a soybean oil refinery plant is typically made from durable materials like stainless steel, ensuring longevity and resistance to corrosion. The choice of material also influences the purity of the oil, preventing contamination during the refining process.

Advantages of Opting for a 5 Ton Refinery

Selecting a 5 ton per day soybean oil refinery comes with several advantages. It is designed for efficiency, capable of processing large batches of soybeans, which is ideal for businesses aiming to scale operations. Additionally, the machinery's design often focuses on energy conservation, reducing operational costs.

Considerations Before Acquisition

Prior to acquiring a soybean oil refinery, factors such as processing capacity, the material being processed, and operating expenses must be evaluated. It is crucial to choose equipment that aligns with your production needs and is within your operational budget, ensuring sustainable operation without undue financial burden.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4