Introduction to Acrylic Paint Production Lines

Acrylic paint production lines are comprehensive systems designed to facilitate the manufacturing of acrylic paints, a popular medium known for its versatility and quick drying properties. These production lines integrate various equipment and processes to deliver a consistent and reliable product used in numerous applications from fine art to home decoration and industrial coatings.

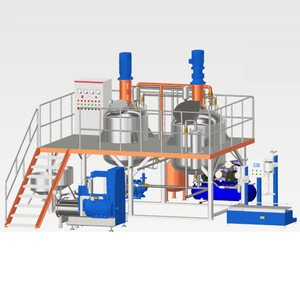

Components and Machinery

A typical acrylic paint production line includes a range of machinery such as mixers, dispersers, mills, and filling equipment. Each component plays a crucial role in the transformation of raw materials into finished paint. Mixers ensure the thorough blending of pigments and binders, dispersers break down pigment agglomerates for uniform color distribution, mills provide the necessary fineness, and filling machines package the paint for distribution.

Materials and Formulations

The materials used in an acrylic paint manufacturing line are pivotal in determining the quality of the end product. These lines handle a variety of raw materials, including pigments, resins, solvents, and additives, each selected for their performance characteristics. The precise formulation impacts the paint's color, texture, durability, and drying time.

Applications and Features

Acrylic paints produced on these lines are employed in diverse sectors, ranging from artistic applications to industrial uses. The features of the paint, such as adhesion, flexibility, and resistance to elements, are tailored to meet the demands of these various applications. This adaptability makes the acrylic paint production equipment a valuable asset for manufacturers aiming to cater to a broad market.

Advantages of Automated Production

Automation in acrylic paint production machinery offers numerous advantages, including enhanced efficiency, consistency in product quality, and reduced labor costs. Automated systems can also be adjusted to produce different types of acrylic paints, allowing for a flexible production line that can respond quickly to market changes.

Environmental Considerations

Modern acrylic paint production systems are designed with environmental considerations in mind. This includes the incorporation of features that minimize waste, promote energy efficiency, and reduce the emission of volatile organic compounds (VOCs), aligning with the growing demand for sustainable manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4