Popular in your industry

Related Searches:

Top categories

About aluminum cutting bending machine

Introduction to Aluminum Cutting Bending Machines

Aluminum cutting bending machines are essential tools in the metal fabrication industry, designed to increase efficiency and precision in metalworking. These machines streamline the process of shaping aluminum sheets, offering a combination of cutting and bending functionalities in one unit. Their primary role is to transform flat aluminum sheets into specific shapes and angles, catering to a wide range of industrial applications.

Types and Applications

The versatility of aluminum bending machines allows them to handle various material thicknesses and types, making them suitable for numerous sectors including automotive, aerospace, and construction. From intricate components to larger architectural elements, these machines are capable of delivering precise bends and cuts to meet diverse design requirements.

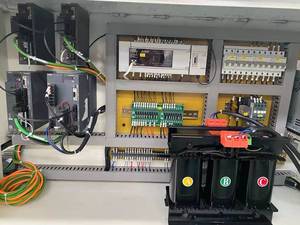

Operational Features

An aluminum sheet bending machine is engineered with features that promote operational efficiency. The bending force, or tonnage, is a critical specification that determines the machine's capability to manipulate metal. With adjustable settings, operators can calibrate the pressure applied to the aluminum, ensuring accurate bends without material waste. Additionally, the integration of cutting technology allows for clean, sharp edges, preparing the material for subsequent manufacturing stages.

Material Efficiency and Waste Reduction

A significant advantage of using an aluminum profile bending machine is its contribution to material efficiency. By optimizing the bending process, the machine ensures minimal offcuts and scrap, which is crucial for cost-effective production. This efficiency not only reduces material costs but also aligns with sustainable manufacturing practices by minimizing waste.

Machine Versatility and Safety

The adaptability of an aluminum plate bending machine extends to its safety features, such as hemming capabilities. Hemming involves folding the edges of cut aluminum sheets to create a safe, rounded finish, thereby reducing the risk of handling injuries. This function is particularly beneficial in producing consumer-facing products where safety and aesthetics are paramount.

Considerations for Purchase

When selecting an aluminum bending machine for sale, it is important to consider factors such as the bending length and the overall size of the machine to ensure it fits within the designated workspace. Prospective buyers should assess the machine's specifications against their project requirements to find a suitable model. For a comprehensive selection of aluminum cutting bending machines, Alibaba.com offers a platform where buyers can connect with suppliers to find equipment that aligns with their operational needs.