Introduction to Car Battery Moulds

The realm of automotive power storage is incomplete without the mention of car battery moulds. These precision tools are the backbone of battery casing manufacturing, providing the essential shapes and sizes for car batteries. As a critical component in the production line, car battery moulds come in various designs to meet the diverse needs of the automotive industry.

Types and Applications

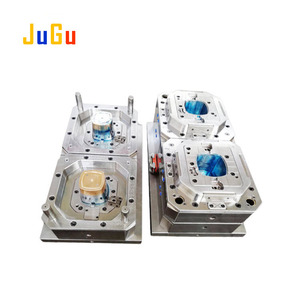

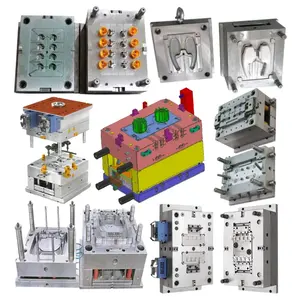

There are several types of moulds, such as the battery container mould, which is specifically crafted to create durable and robust casings for car batteries. These moulds are not just limited to creating standard sizes but can also be customized to accommodate innovative battery designs. The applications of these moulds are extensive, supporting the production of batteries for various vehicle types, from passenger cars to heavy-duty trucks.

Features and Materials

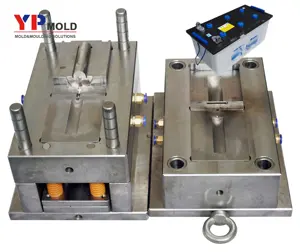

A car battery mould must possess certain features to ensure it meets the industry's stringent standards. Precision, durability, and thermal resistance are among the top requirements. The materials used for these moulds, such as iron or specialized alloys, are selected based on their ability to withstand high pressures and temperatures during the injection moulding process.

Advantages of Quality Moulds

Investing in a well-crafted car battery mould brings several advantages. It ensures consistency in production, essential for meeting both safety and quality standards. Moreover, a well-designed mould can significantly reduce production time and material waste, contributing to more efficient manufacturing processes.

Customization and Standardization

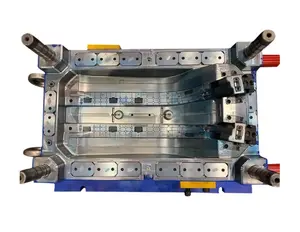

Customization plays a pivotal role in the utility of a car battery mould. Manufacturers can tailor moulds to specific design requirements, ensuring that each battery fits perfectly within its designated space in a vehicle. On the other hand, standardization of certain mould elements, like connection sizes and clamp slots, can streamline the manufacturing process, making it easier to switch between different mould types with minimal downtime.

Choosing the Right Mould

Selecting the right car battery mould is crucial for manufacturers. It involves considering the design, material, and the specific requirements of the battery being produced. Suppliers on Alibaba.com offer a range of options, allowing buyers to find moulds that align with their production needs without the hassle of navigating through countless retailers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4