Understanding Centrifugal Motor Start Switches

A centrifugal motor start switch is an essential component in single-phase electric motors, playing a pivotal role in the initiation and operation of the motor. This type of switch is specifically designed to engage or disengage the start winding of the motor once it reaches a predetermined speed, ensuring efficient performance.

Types and Applications

The applications of a centrifugal start switch are diverse, ranging from household appliances to industrial machinery. The switch is a critical part of a capacitor start motor centrifugal switch assembly, which is commonly found in motors that require a high starting torque. These switches are integral to the functionality of pumps, blowers, and power tools, among other equipment.

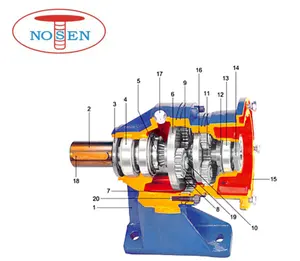

Features and Materials

When considering a centrifugal motor start switch, it's important to note the robust materials used in its construction, which contribute to the switch's durability and reliability. The switch typically comprises a metallic body, often with a plastic or composite cover, and includes electrical contacts designed for repeated use. The precise operation of the switch is facilitated by springs and weights that are calibrated for specific motor speeds.

Advantages of Centrifugal Switches

The advantages of incorporating a centrifugal switch capacitor start motor are numerous. These switches are designed for efficiency, automatically disconnecting the auxiliary winding of the motor once it reaches the required speed. This action helps in reducing electrical consumption and improving the motor's longevity. Additionally, the self-actuating nature of the switch minimizes the need for manual intervention, streamlining the motor's operation.

Selection Considerations

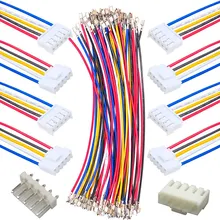

Selecting the right centrifugal motor start switch involves several considerations. Capacity, which refers to the number of ports on the switch, is crucial for ensuring that it can handle the intended number of connections. Speed is another factor, as the switch must be able to operate effectively with the motor's speed. Configuration is also key, as it determines how the switch integrates with the motor and the ease of setup. Lastly, scalability should be considered for future expansion needs.

Maintenance and Repair

For maintenance and longevity, electric motor centrifugal start switch repair is a service that may be required to ensure the continuous and efficient operation of the motor. Regular checks and timely repairs can prevent motor failure and extend the service life of the equipment.

In summary, a centrifugal motor start switch is a critical component for single-phase motors, offering a range of benefits from high starting torque to improved efficiency. When selecting a switch, it is important to consider the specific needs of the motor it will serve, including capacity, speed, and configuration. For those looking to maintain or repair their motor's switch, understanding the basics of how a centrifugal motor start switch functions can be invaluable.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4