Introduction to Chrome Spraying Equipment

Chrome spraying equipment represents a specialized category within metal finishing technology, designed to enhance and protect metal surfaces. This equipment is pivotal in various industries, enabling the application of chrome finishes to a wide range of products.

Types of Chrome Spraying Systems

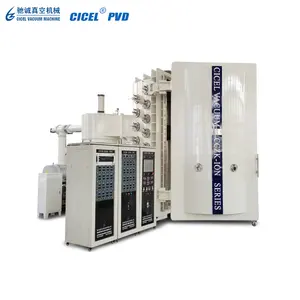

The diversity of chrome spraying systems caters to different industrial needs. Powder coating systems are prevalent for their durability, providing an even, long-lasting finish. Electrostatic paint coating machines offer precision, favored in automotive manufacturing. Vacuum coating machines, employing thin film deposition, are ideal for applications requiring high tolerance and resilience without the bulk of paint-based coatings.

Applications of Chrome Coating Machinery

Chrome coating machinery is versatile, serving numerous sectors. Outdoor furniture benefits from weather-resistant finishes, while automotive components gain aesthetic appeal and protection. The technology is also instrumental in producing robust tools and products that withstand environmental stressors.

Features of Chrome Spraying Equipment

Modern chrome spraying equipment features advanced technology to ensure efficient and uniform application of chrome coatings. High-pressure systems facilitate powder coatings that adhere strongly to metal surfaces, while vacuum coating machines apply protective layers with precision.

Materials and Advantages of Chrome Finishing

Chrome finishing uses a variety of materials, including different metallic powders and solutions, tailored to the desired outcome. The advantages of using chrome finishing equipment include enhanced durability, improved resistance to corrosion, and an increase in the aesthetic value of the metal products.

Choosing the Right Chrome Spraying Equipment

Selecting the appropriate chrome spraying equipment involves considering the specific requirements of the task at hand. Factors such as the type of metal, the desired finish, and the production environment play crucial roles in determining the most suitable machinery.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4