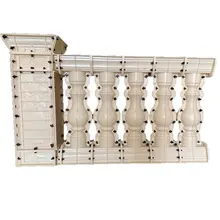

Exploring Concrete Molds for Rail Fences

Concrete molds for rail fences are essential tools in the construction and landscaping industries, enabling the production of durable and uniform barriers. These molds are designed to shape and support concrete until it hardens and can be used to create various styles of rail fencing that are both functional and aesthetically pleasing.

Types and Applications

There is a diverse range of concrete molds for rail fences to suit different project requirements. From simple, straight barriers to more ornate designs, these molds cater to a variety of applications such as property boundaries, decorative garden enclosures, and safety barriers in commercial settings. The adaptability of these molds allows for their use in both small-scale residential projects and larger, industrial applications.

Material and Features

The materials used in the construction of concrete fence molds are selected for their strength and durability. Iron is a common choice, providing a robust framework for the concrete. Other materials, such as plastics or composites, are also utilized depending on the intricacy and finish required for the fence design. Features of these molds include ease of use, reusability, and the ability to produce a consistent finish with each use.

Advantages of Using Concrete Molds

Utilizing concrete molds for rail fencing offers several advantages. They provide a cost-effective solution for mass production, ensuring uniformity and consistency in the final product. The longevity of the molds means they can be used repeatedly, reducing overall project costs. Additionally, the flexibility in design allows for customization to meet specific aesthetic or functional needs.

Customization and Standardization

Customization is a key aspect when selecting a concrete rail fence mold. Molds can be tailored to specific design requirements, ensuring the final product meets the desired specifications. Standardization of certain mold elements, such as lift bars and clamp slots, can further streamline the manufacturing process, making it more efficient and compatible with various production setups.

Selecting the Right Mold

Choosing the appropriate concrete mold for a rail fence is crucial for project success. Factors to consider include the design complexity, the material of the mold, and the expected production volume. Suppliers on Alibaba.com offer a wealth of information to assist buyers in making an informed decision, ensuring they find a mold that aligns with their project requirements and production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4