Introduction to Condenser Fin Making Machines

The realm of thermal management and heat exchange is intricate, with the condenser fin making machine playing a pivotal role. This machinery is specialized in the production of fins for condensers, which are essential components in various cooling systems. The condenser fin serves as a heat exchanger, facilitating the transfer of heat from a gas or liquid to a cooler medium.

Types and Applications

There are multiple types of condenser fin production equipment, each designed to meet the diverse needs of manufacturing plants and construction sectors. These machines are adept at serving industries that require precise and efficient thermal management solutions, such as automotive, HVAC (Heating, Ventilation, and Air Conditioning), and refrigeration industries. The versatility of these machines allows for their application in building material shops where specific fin designs are required.

Technical Features and Specifications

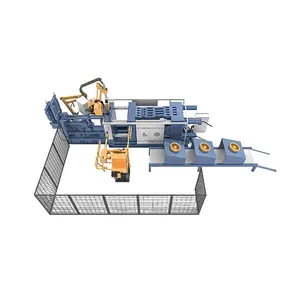

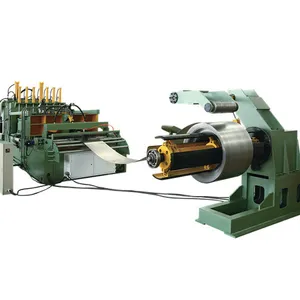

The technical features of a condenser fin press are tailored to enhance production efficiency and fin precision. Typically, these machines operate with a voltage standard of 380v, although specifications may vary to accommodate different industrial requirements. The machinery may include options such as fully automatic operation, roll forming capabilities, and hydraulic pressing processes, ensuring adaptability to various production lines.

Materials and Construction

Condenser fin manufacturing machines are constructed to handle a range of materials, including but not limited to aluminum, copper, and alloy composites. These materials are chosen for their thermal conductivity and durability, which are critical for the performance of the fins in heat exchange systems. The robust construction of the machines ensures longevity and reliability in industrial settings.

Advantages of Modern Fin Making Solutions

Modern fin making machines for condensers offer several advantages. They are designed for energy efficiency, reducing operational costs while maintaining high productivity. The precision engineering of these machines leads to high-quality fin production with minimal material wastage. Furthermore, the integration of advanced controls and programming enhances the ease of operation and allows for customization in fin design.

Support and Services

While exploring the options for a condenser fin making machine on Alibaba.com, buyers can anticipate a spectrum of support services. These may include access to online support, video technical assistance, and the availability of engineers for service machinery guidance. It is important to note that the specific services offered are dependent on the suppliers and their terms.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4