Popular in your industry

Related Searches:

Top categories

About core drills bits

Exploring Core Drill Bits

Core drill bits are essential tools in the construction and renovation industries, designed for creating precise holes in a variety of materials. These bits are integral to various applications, from installing fixtures to creating passageways for plumbing and electrical work. Understanding the nuances of core drill and bits is crucial for professionals seeking efficient and accurate drilling solutions.

Types and Applications

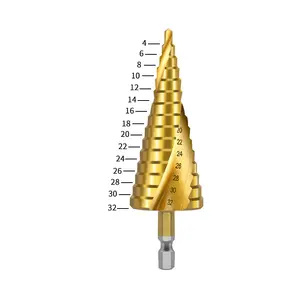

The versatility of core bits is evident in their range of types, each suited to different materials and applications. For instance, concrete core drill bit options are tailored for masonry and concrete, offering the durability needed to penetrate hard surfaces. On the other hand, dry core bits are designed for dry drilling scenarios, often used when water application is not feasible. The selection of a core bit is determined by the specific requirements of the task at hand, whether it's drilling through plasterboards, wood, aluminum, or even dense stoneware tiles.

Features and Materials

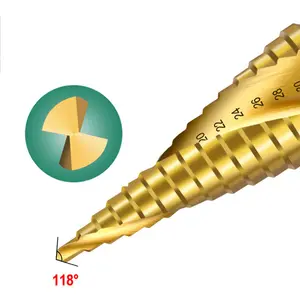

The construction of core drill bits is a testament to engineering designed to meet the demands of tough drilling conditions. Diamond core drill bits are a prime example, featuring diamond tips that offer resilience and precision. This makes them an ideal choice for tasks requiring small diameter holes in challenging materials. Similarly, hilti core drill bits are recognized for their robustness, often selected for heavy-duty drilling operations. The materials and design features of core bits contribute significantly to their performance and longevity.

Advantages of Precision Tools

The advantages of using specialized core drill bits like 100mm core drill or core bit set are manifold. These tools are engineered to minimize overheating and ensure a longer lifespan with proper use, such as the application of cold water during drilling to prevent damage. Furthermore, the ability to adjust the drilling speed allows for enhanced control, enabling a gradual increase in speed that corresponds with the depth of the bit and the material being drilled.

Maintenance and Care

Maintaining the sharpness and efficiency of core drill bits is straightforward. For instance, paddle bits, known for their wide and flat blade, can be easily sharpened with a regular or diamond file, ensuring consistent performance. Proper care and maintenance not only extend the life of the bits but also ensure clean and precise holes, which is critical in professional settings.

Choosing the Right Bit

Selecting the right core diamond drill or bit is pivotal for the success of any drilling project. Factors such as material hardness, the diameter of the hole, and the presence of abrasive materials all play a role in determining the most suitable bit. It is essential to match the bit to the specific requirements of the job to achieve optimal results without compromising the integrity of the tool or the material.