Introduction to Corn Curls Making Machines

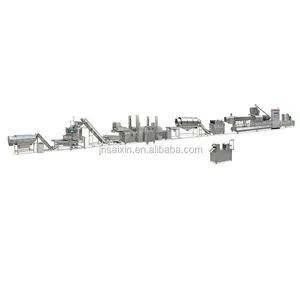

The corn curls making machine stands as a cornerstone in the snack production industry, catering to businesses that aim to deliver a variety of crunchy treats to the market. These machines are engineered to transform raw materials into the beloved twisty snacks known as corn curls. With efficiency and consistency, they serve as a pivotal asset for snack manufacturers.

Types and Applications

There is a diverse array of corn curls production equipment available, each designed to meet specific production needs. From compact models suitable for small-scale operations to industrial-grade machines for high-volume production, the versatility in applications is vast. These machines are adept at handling different ingredients and recipes, making them suitable for a range of corn-based snacks beyond just curls.

Features and Materials

A typical corn curls extruder is constructed from food-grade stainless steel, ensuring durability and adherence to food safety standards. Advanced models come equipped with intuitive control panels for precise adjustments during the production process. Features often include variable speed settings, temperature control, and automated cutting mechanisms, which collectively contribute to the machine's ability to produce snacks with consistent shape and texture.

Advantages of Utilizing Corn Curls Machines

Employing a snack extruder machine in your production line can significantly enhance operational efficiency. These machines are designed for ease of use, requiring minimal training for operation. The automation they provide reduces labor costs and increases production capacity. Moreover, the consistent quality of the output can bolster a brand's reputation for reliability in the snack market.

Choosing the Right Machine

Selecting the appropriate corn snack making machine involves considering production volume, available space, and the specific snack varieties planned for production. Suppliers on Alibaba.com offer a spectrum of machines, each with detailed specifications to aid buyers in making an informed decision that aligns with their operational requirements.

Operational Efficiency and Safety

Modern corn curls machines are not only designed for efficiency but also prioritize operator safety and food hygiene. The automated process minimizes human contact with the food product, thereby reducing the risk of cross-contamination. This aspect is crucial for businesses that aim to maintain high standards of food safety and quality assurance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4