Exploring Corrugated Cardboard Machine Manufacturing

In the realm of corrugated cardboard machine manufacturing, refined keywords denote the advanced and precise technologies integral to producing corrugated cardboard. This material is extensively utilized for its durability and protective attributes in packaging and shipping. These keywords are crucial to the machinery's functionality, forming the industry's foundation. The machines are tailored for a range of businesses, encompassing packaging, retail, and manufacturing sectors that demand reliable and uniform corrugated cardboard production.

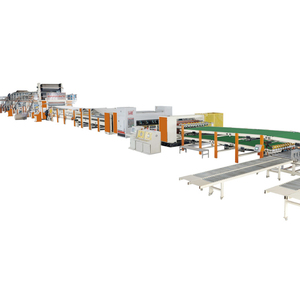

The corrugated cardboard production process encompasses multiple phases, each facilitated by specialized machinery and equipment. Initially, rolls of paper are introduced into a machine that imprints the corrugation pattern, crafting the flutes. Following the formation of flutes, the paper is adhered to create a robust structure, ready to be transformed into various packaging solutions like boxes and trays. These machines incorporate technologies such as Computerized Numeric Control (CNC) systems to guarantee precision throughout their operation.

Refined keywords play a critical role in articulating the capabilities and advantages of these machines. Manufacturers employ these terms to underscore distinguishing features of their offerings, including speed, material efficiency, and automation levels. For entities considering an investment in corrugated cardboard machines, grasping these refined keywords is instrumental in selecting equipment that meets their unique production requirements.

Varieties of Corrugated Cardboard Machine Manufacturing

The field of corrugated cardboard machine manufacturing is diverse, with a spectrum of machine types serving different production process facets. Each category is engineered to fulfill distinct functions within the manufacturing setting:

-

Single Facer Corrugating Machine: A cornerstone in corrugated cardboard production, this machine etches the fluted pattern on one side of the cardboard sheet, conferring rigidity and strength. It is typically paired with additional machines for subsequent processing.

-

Double Facer Corrugating Machine: Known also as a double backer, this machine affixes a second fluted paper layer to one side of the corrugated sheet, crucial for enhancing board strength and achieving the final product's desired characteristics.

-

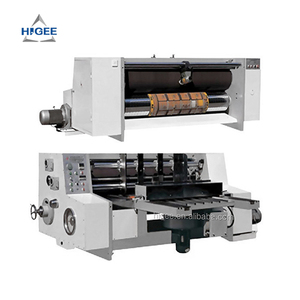

Corrugated Slitter Machine: This machine segments corrugated sheets into narrower strips, proving invaluable for tailoring box sizes to diverse packaging demands.

-

Corrugated Box Making Machine: An all-encompassing system capable of managing the entire process from printing to die-cutting, suitable for large-scale industrial production and a multitude of box styles.

-

Corrugated Sheet Stacker Machine: Post cutting and folding, this machine accumulates sheets into bundles or pallets, a vital step in readying products for distribution.

Selecting Corrugated Cardboard Machine Manufacturing

Choosing the appropriate corrugated cardboard machine necessitates careful evaluation of various factors. As companies seek to procure these machines for operational or commercial use, it is crucial to consider the production scale required, the types of corrugated board produced, and the specific processes involved.

For packaging industry players needing high-speed production with minimal downtime, a fully automatic corrugated cardboard machine is likely the optimal choice. Such machines automate tasks like gluing, drying, and stacking, enhancing efficiency.

Conversely, enterprises focusing on smaller-scale or specialized packaging might prefer semi-automatic or manual machines, which offer lower upfront costs and more flexibility in material and production rates.

The decision between single facer, double facer, or rotary die machines hinges on the complexity of your product's packaging requirements. A single facer may suffice for straightforward boxes, whereas double facer machines are more apt for larger operations with complex box designs.

Additionally, the after-sales support and maintenance services offered by the supplier warrant consideration. Services such as video technical support and field maintenance are essential for maintaining smooth machinery operation over time.

In essence, selecting the right corrugated cardboard machine is a balance between the benefits of automation and the cost-effectiveness of manual labor, tailored to your business's specific needs.

About Corrugated Cardboard Machine Manufacturing on Alibaba.com

Alibaba.com distinguishes itself as a global marketplace that bridges businesses with a comprehensive selection of suppliers providing various corrugated cardboard machines. The platform showcases a range of options from compact box makers to extensive production lines, each designed to fulfill distinct industrial requirements. Alibaba.com's dedication to streamlining international trade is reflected in its intuitive interface, robust services like Trade Assurance, and proficient order processing.

Companies in the market for corrugated cardboard machines will find Alibaba.com's extensive supplier network exceedingly beneficial. The platform's focus on verified suppliers guarantees confidence in sourcing machinery that meets stringent quality standards. Moreover, Alibaba.com's capacity to accommodate custom requests enables you to tailor equipment to your operational exigencies, whether for high-volume output or specialized packaging solutions.

Alibaba.com's international scope provides businesses from over 190 countries access to state-of-the-art corrugated cardboard machine technology. With secure transaction guarantees and comprehensive support services throughout the purchasing process, Alibaba.com stands as a dependable ally in enhancing packaging operations globally.

Common FAQs for Corrugated Cardboard Machine Manufacturing

What distinguishes single-faced from double-faced corrugated cardboard?

Single-faced corrugated cardboard features a solitary liner board on one side, typically employed for lightweight packaging and displays, whereas double-faced corrugated cardboard, with liner boards on both sides, is more suitable for robust packaging and high stacking demands.

Is it possible to tailor corrugated cardboard to specific packaging requirements?

Absolutely, corrugated cardboard can be customized in dimensions, thickness, flute type, and print design to accommodate diverse packaging needs for various products and applications.

What considerations are important when choosing the flute type for my corrugated cardboard?

When choosing the flute type, it's important to account for the required strength-to-weight ratio, the desired box rigidity, and the need for cushioning to protect delicate items.

What after-sales services are available for corrugated cardboard machines?

After-sales services for corrugated cardboard machines may encompass video technical support, online assistance, engineers for overseas machinery servicing, and field maintenance and repair services, though availability may differ by supplier.

How do I ascertain the suitable machine size for my corrugated cardboard requirements?

The suitable machine size is contingent on your production volume and the specific dimensions of the corrugated sheets you intend to utilize. It's crucial to select a machine capable of accommodating your anticipated volume without quality compromise.

What after-sales service should I seek when purchasing a corrugated cardboard machine?

Seek after-sales services such as video technical support, online assistance, and engineers for overseas machinery servicing. These services are vital for troubleshooting and maintaining your equipment in prime condition.

How can I ensure the purchased corrugated cardboard machine's durability?

To guarantee durability, opt for machines crafted from high-grade materials like steel and robust components. Additionally, consider equipment from suppliers renowned for their reliable machinery.

Can I locate a supplier offering local service locations for my corrugated cardboard machine?

Several suppliers on Alibaba.com provide machinery test reports and may offer local support for the installation and maintenance of your corrugated cardboard machine.

Is obtaining a machinery test report for my corrugated cardboard machine feasible?

Securing a machinery test report generally depends on the supplier's policy. It's imperative to express your need for this document during negotiations.

Which core components should be prioritized when purchasing a corrugated cardboard machine?

Focus on core components such as PLC systems, motors, bearings, gearboxes, and pressure vessels. The caliber and dependability of these elements can significantly influence your machine's performance and lifespan.

Is customization available if my packaging requirements are unique?

Yes, numerous suppliers on Alibaba.com offer customization options. Discuss your specific requirements, including dimensions, material preferences, and additional features, during the negotiation phase.

How does the automatic grade impact my corrugated cardboard machine selection?

The automatic grade determines the extent of manual intervention during operations. Opting for a machine with a higher automatic grade can reduce labor costs and potentially enhance throughput.

What packaging types can be produced with a corrugated cardboard machine?

Corrugated cardboard machines are capable of crafting a variety of packaging solutions, such as boxes, cartons, and displays. The type of packaging producible is contingent on the chosen machine's capabilities.

Are eco-friendly options available among corrugated cardboard machines?

Certain suppliers offer environmentally conscious options that utilize recycled materials or feature energy-saving capabilities. It's advisable to inquire with individual suppliers regarding their sustainable products.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4