Popular in your industry

Top categories

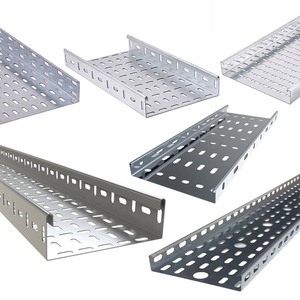

About galvanised cable trunking

Introduction to Galvanised Cable Trunking

Galvanised cable trunking is an essential component in modern cable management systems, designed to protect, route, and organize cables and wires across various settings. This robust solution, crafted from galvanised steel, ensures durability and longevity, safeguarding electrical systems from environmental factors and interference.

Types and Applications

The versatility of galvanised cable trunking is evident in its range of types and applications. From 100mm galvanised trunking suitable for larger cable bundles to 50mm galvanised trunking for more refined spaces, each variant serves a specific purpose. In industrial environments, hot dip galvanised trunking is often employed due to its superior resistance to corrosion, making it ideal for harsh conditions. Electro galvanised trunking, on the other hand, is frequently used in commercial and residential buildings for its sleek appearance and effective protection.

Features and Advantages

The features of galvanised metal trunking include its high resistance to corrosion, mechanical protection, and ease of installation. These features translate into advantages such as enhanced safety, reduced maintenance costs, and improved aesthetics. The use of galvanised electrical trunking not only extends the lifespan of cable systems but also supports a clean and organized layout, crucial for systematic operations in facilities like laboratories and factories.

Customization and Integration

Integration into existing systems is streamlined with options like 2 compartment galvanised trunking and 3 compartment galvanised trunking, which allow for separation and categorization of different cables. For specific spatial requirements, 100 x 100 galvanised trunking and 50 x 50 galv trunking provide tailored solutions that fit precise dimensions. The adaptability of galvanised metal cable trunking is further enhanced by the possibility of creating custom lengths and bends, ensuring a perfect fit for any application.

Material and Construction

The construction of galvanised steel trunking involves a meticulous process that coats the steel with a layer of zinc, offering protection against rust and deterioration. This process, known as galvanization, can be performed through hot-dipping or electro-galvanization, each method imparting different characteristics to the trunking, such as the rugged thickness of hot dipped galvanized trunking or the smooth finish of electro-galvanised variants.

Selection Considerations

When selecting the appropriate trunking, factors such as environmental conditions, cable type, and load requirements should be considered. For instance, 2x2 galv trunking might be suitable for light-duty applications, whereas heavier setups may necessitate 50x50 galv trunking or larger. The choice of trunking impacts not only the protection of cables but also the efficiency of installation and future maintenance.