Popular in your industry

Top categories

About high density foam rod

A high-density foam rod is a versatile and resilient industrial material. These rods, which are used across a myriad of applications, are fashioned from a variety of materials including rubber, PE foam, EPDM, CR, PVC, aluminum, XPE, NBR, and metals to suit specific application needs. Their shock-resistant and waterproof properties make them invaluable across industries such as construction and manufacturing.

Types and Materials of High-Density Foam Rods

The high-density foam rod category includes a diverse assortment of products, each tailored with distinct characteristics for particular uses. EVA foam rods are prized for their softness and pliability, commonly utilized in sporting goods and toys. Conversely, PE foam rods provide a sturdier structure, apt for industrial purposes like pipe insulation and filling voids. EPDM rods are selected for their superior resistance to weather and ozone, making them suitable for exterior uses. Each rod type is engineered with specific properties in mind, such as compressibility, tensile strength, and thermal conductivity, to fulfill the exacting demands of various commercial applications.

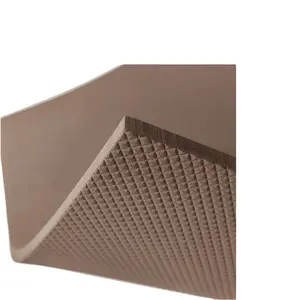

Structure and Functionality of High-Density Foam Rods

The intricate design of a high-density foam rod is no accident. Its cellular makeup, either open-cell or closed-cell, is pivotal, with the latter providing enhanced waterproofing and airtightness. This configuration is crucial for insulation applications, as it governs the rod's capacity to trap air and act as a thermal barrier. The rod's components, including the skin and core, collaborate to achieve the desired outcome, be it for absorbing impacts in packaging or offering a resilient yet flexible seal in construction joints.

Materials and Properties

The selection of materials for high-density foam rods hinges on their inherent properties. Rubber and NBR are chosen for their elasticity and robustness, ideal for crafting seals and gaskets. PE foam stands out for its chemical resistance and minimal water uptake, while EPDM is notable for its UV and extreme temperature resilience, ensuring durability in severe conditions. These materials confer multiple advantages, such as heightened safety, enhanced energy efficiency, and diminished maintenance expenses.

Business Usages and Applications

High-density foam rods serve a wide array of commercial functions. In the realm of construction, they act as backer rods, buttressing sealants in joints to prevent three-sided adhesion and facilitate proper sealant dynamics. Within the automotive industry, they are instrumental in soundproofing and reducing vibration. In packaging, they safeguard merchandise by mitigating shocks during transportation. These uses not only bolster product performance and longevity but also enhance safety and comfort, aiding businesses in complying with regulations and satisfying consumer expectations.

Functions and Tasks

The primary role of a high-density foam rod is to serve as a filler, insulator, or buffer. In the construction sector, they occupy voids to prime for caulking, ensuring seals are both airtight and watertight. In manufacturing settings, they mitigate vibrations in machinery, safeguarding components from wear. The specific duties these rods undertake are as varied as their types, with each material providing distinct functional advantages.

Features and Unique Selling Points

Key attributes of high-density foam rods include their exceptional compression recovery, guaranteeing long-term shape retention and efficacy. Another hallmark is their compatibility with a broad spectrum of sealants and adhesives, rendering them a versatile option for numerous industries. These features distinguish them from competitors, offering a blend of durability, adaptability, and performance that is difficult to surpass.

Benefits and Positive Outcomes

The advantages of employing high-density foam rods are manifold. They offer an economical approach to thermal and acoustic insulation, curtail material wastage through precise application, and enhance the aesthetic quality of finished joints by promoting uniform sealant distribution. The resultant benefits include improved energy efficiency in edifices, extended machinery lifespan via vibration attenuation, and superior product protection during transit.

How to Use High-Density Foam Rods

Optimal utilization of high-density foam rods entails choosing the correct size and compressing it into the joint or gap prior to sealant application. This ensures a snug fit and prevents the sealant from drooping or dislodging over time. For packaging purposes, rods should be accurately cut and strategically positioned to afford maximal protection.

How to Choose the Right Foam Rod

Selecting the appropriate high-density foam rod demands an understanding of the specific requirements of the application. Considerations should include the gap size, environmental exposure, and the type of sealant employed. It is also crucial to align the rod's density and compressibility with the load-bearing demands of the application.

How to Clean and Maintain High-Density Foam Rods

Cleaning high-density foam rods typically involves a simple wipe-down with a clean, damp cloth. For maintenance, it is essential to store them in a manner that prevents deformation and to routinely check for signs of wear, replacing them as needed to ensure sustained performance.

How to Install High-Density Foam Rods

Installing high-density foam rods is straightforward but requires precision to guarantee effectiveness. In construction, accurately measure the joint's depth and width to select the proper size. The rod should be firmly pressed into the joint, allowing for the recommended sealant depth on top. For other applications, adhere to the manufacturer's installation guidelines to secure the best outcomes.

What are the customization options for high-density foam rods?

Many manufacturers offer customization of high-density foam rods to cater to specific business requirements. Options range from various lengths, diameters, and densities to the inclusion of adhesive backings. Custom shapes can also be crafted to fit unique spaces or fulfill specialized roles.

Are high-density foam rods environmentally friendly?

The environmental footprint of high-density foam rods is contingent on the materials utilized. An increasing number of foam rods are crafted from eco-conscious materials that are either recyclable or boast a reduced environmental impact. Businesses prioritizing sustainability should seek out products that reflect these principles.

What should be considered when storing high-density foam rods?

Correct storage of high-density foam rods is vital to preserving their quality. They should be stowed in a cool, dry environment, shielded from direct sunlight and heat sources to avert deformation or deterioration. Additionally, it is important to store them in a manner that avoids compression or distortion, which could compromise their functionality.