Popular in your industry

Related Searches:

Top categories

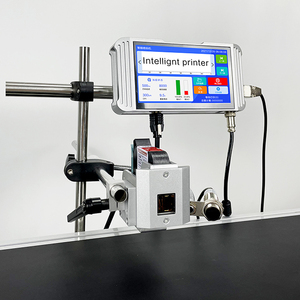

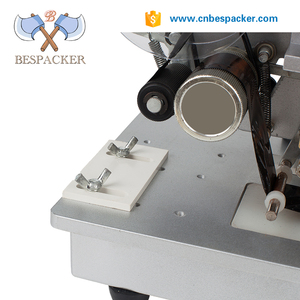

About hot coding machine

A hot coding machine is a device that is used to print production dates, expiration dates, and batch numbers on various packaging materials. This machine is widely used in industries like food, pharmaceuticals, cosmetics, and others that require precise and legible coding on their packaging. The coding can be done with different types of materials, such as hot ink rolls, hot stamping foils, and colored ribbons. The primary function of the hot coding machine is to provide a quick and efficient way to mark important information on products for identification and traceability purposes.

Types of hot coding machines

There are several types of hot coding machines available in the market, each with its unique features and applications. The most common types include hot ink roll coding machines, hot stamping or hot foil coding machines, and color ribbon hot printing machines. Hot ink roll coding machines use a heated ink roll to transfer the ink onto the packaging material. This type of machine is suitable for printing on non-porous surfaces like plastic films and glossy paper. Hot stamping or hot foil coding machines use a heated die to transfer the foil onto the packaging material. This type of machine is ideal for printing on surfaces that require a more permanent and durable mark, such as labels and flexible packaging. Color ribbon hot printing machines use a heated print head to transfer colored ribbons onto the packaging material. This type of machine is used when color coding is required for product identification or branding.

Advantages of hot coding machines

Hot coding machines offer several advantages, making them a popular choice for industries that require precise and high-quality coding on their packaging. One of the key advantages of hot coding machines is their ability to provide consistent and clear coding on various packaging materials. The use of heat ensures that the coding is well-defined and legible, even on challenging surfaces. Additionally, hot coding machines are versatile and can be used to print different types of information, including batch numbers, expiration dates, and logos. This flexibility makes them suitable for a wide range of products and industries. Furthermore, hot coding machines are cost-effective and easy to operate. They require minimal maintenance and consumables, making them a practical choice for businesses of all sizes. Lastly, hot coding machines contribute to improved product traceability and compliance with regulatory requirements. By providing accurate and permanent coding on the packaging, these machines help in identifying and tracking products throughout the supply chain.

Applications of hot coding machines

The application of hot coding machines is extensive, especially in industries that require precise and durable coding on their packaging. In the food industry, hot coding machines are used to print essential information like production dates and batch numbers on food packaging. This coding is crucial for food safety and compliance with regulations. Similarly, in the pharmaceutical industry, hot coding machines play a vital role in marking expiration dates and serial numbers on drug packaging. This coding ensures the integrity and traceability of pharmaceutical products. Hot coding machines are also widely used in the cosmetic industry to print logos, ingredients, and other details on cosmetic packaging. Additionally, these machines find applications in industries like automotive, electronics, and manufacturing, where product identification and traceability are essential. The adaptability and efficiency of hot coding machines make them a valuable asset for businesses seeking reliable and high-quality coding solutions.