Popular in your industry

Top categories

About hyundai flux cored welding wire

Understanding Hyundai Flux Cored Welding Wire

Flux cored welding wire, particularly the Hyundai flux cored welding wire, stands as a pivotal component in the welding industry. This specialized wire is crafted to facilitate an electric arc that fuses metals together, a process integral to various sectors such as construction, automotive, and shipbuilding. The wire's core contains flux, which can significantly influence the mechanical properties of the weld.

Types and Features of Flux Cored Wires

There are several types of flux cored wires available, each designed for specific welding tasks and base metals. The selection includes gas-shielded and self-shielded options, each with unique attributes. Gas-shielded wires, often used in heavy industrial applications, require an external shielding gas and are known for their consistent welding performance. Self-shielded wires, on the other hand, are more adaptable to outdoor conditions and offer greater flexibility in mobility.

Applications and Advantages

The Hyundai flux cored welding wire is versatile, finding its place in industries that demand robust and reliable welding solutions. Its use spans from intricate automotive repairs to the sturdy requirements of shipbuilding. The advantages of using flux cored wires include higher deposition rates, excellent penetration, and an ability to weld through contaminants, making them suitable for a variety of applications.

Selection Criteria for Welding Wire

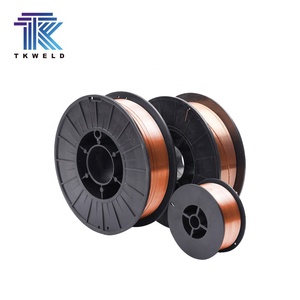

Choosing the right welding wire is crucial for the success of any welding operation. Factors such as the material to be welded, the welding position, and the desired finish must be considered. The diameter of the wire also plays a significant role, affecting the welding process's overall efficiency and outcome. The Hyundai flux cored welding wire comes in various diameters to cater to different requirements and preferences.

Enhancing Weld Quality and Productivity

Employing the appropriate Hyundai flux cored welding wire can lead to improvements in weld quality and productivity. These wires are engineered to produce less splatter, reduce the need for post-weld cleanup, and provide stronger welds compared to other types of wires. Their design allows for continuous welding, which can enhance the efficiency of the welding process.

Conclusion

In conclusion, the Hyundai flux cored welding wire is a critical element in the welding sector, offering a blend of versatility, efficiency, and strength. While Alibaba.com serves as a platform connecting buyers with a wide array of suppliers, it is essential to consider the specific requirements of your welding project to select the most suitable wire.