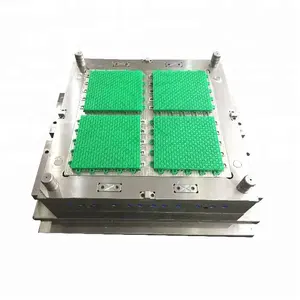

Introduction to Injection Molds for Plastic Floor Tiles

Injection molding is a versatile manufacturing process used for producing a wide array of products, including plastic floor tiles. This method involves injecting molten plastic into a mold to create items with precise dimensions and intricate designs. The injection mold for plastic floor tile category encompasses a variety of molds designed to meet the specific needs of the flooring industry.

Types and Applications

The types of molds available vary based on the application and design complexity. From simple, geometric patterns to more complex, decorative tiles, the application of injection molding technology caters to both functional and aesthetic requirements. These molds are not just limited to residential flooring but are also used in commercial and industrial settings, where durability and design variety are crucial.

Features and Materials

An injection mold for plastic floor tile is characterized by its robust construction and ability to withstand high pressures of the injection molding process. Materials used in mold making include metals like iron, which is known for its strength and longevity. The choice of material for the mold impacts the quality and detail of the finished tile, as well as the mold's lifespan and performance.

Advantages of Injection Molding for Flooring

The injection molding process offers several advantages for manufacturing plastic floor tiles. It allows for high-volume production with consistent quality and intricate detailing. Additionally, the process is efficient, with a fast turnaround time from design to final product. The adaptability of plastic injection molds means they can be tailored to create unique tile designs that meet specific customer requirements.

Optimizing Production with Standardization

To enhance production efficiency, elements of the injection mold can be standardized. This includes lift bars, connection sizes, and clamp slots, which can be uniform across different molds. Such standardization facilitates ease of use and interchangeability, potentially reducing production costs and downtime.

Choosing the Right Mold for Your Needs

Selecting the appropriate injection mold for plastic floor tile production is a critical decision. It involves considering the design, material, and specific requirements of the tile. Suppliers on Alibaba.com offer a range of options and can provide guidance on the most suitable mold for your application, ensuring that the final product meets your expectations without making explicit guarantees.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4