Popular in your industry

Top categories

About interlining roll

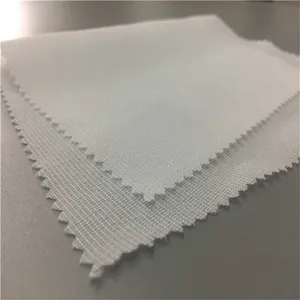

Understanding Interlining Rolls

Interlining rolls are a fundamental component in the textile industry, serving as a critical layer between fabrics to provide structure and support. These rolls are predominantly utilized in the production of garments, offering a variety of interlining options to meet diverse fabric needs. The versatility of interlining fabric makes it a staple in clothing manufacturing, where it is used to enhance the aesthetic and functional qualities of the final product.

Types and Features of Interlining Rolls

The range of interlining roll types is extensive, catering to different applications and fabric characteristics. Among these, nonwoven interlining rolls are prominent, known for their adaptability and ease of use in various garment sections. Another category, woven interlining rolls, provides a different set of attributes, including stability and strength, which are essential for structured garments. Features such as stretchability and shrink-resistance are also available, allowing designers to maintain the integrity and shape of the apparel over time. Coatings and treatments like double dot or PA (polyamide) enhance the bond between fabrics, ensuring durability and longevity.

Applications of Interlining Rolls in Garment Production

Garment interlining is a critical application of interlining rolls, where they are used to reinforce areas of a garment that require additional support or structure, such as collars, cuffs, and waistbands. The choice of interlining—whether fusible or sew-in—depends on the garment's design and the desired finish. The use of interlining in cloth and garment production not only improves the appearance but also enhances the performance of the clothing item, providing shape retention and comfort.

Materials and Advantages of Interlining Rolls

Interlining materials range from polyester to cotton blends, each offering unique benefits. Polyester interlinings, for instance, are known for their resilience and ease of maintenance, while cotton blends provide a softer touch and natural breathability. The advantages of using fusible interlining rolls include time-saving in the production process and uniformity in application, which are crucial for mass production. On the other hand, non-fusible interlinings, which are sewn into the garment, offer flexibility and are often preferred for more delicate fabrics.

Selection Criteria for Interlining Rolls

Selecting the right interlining material is paramount to achieving the desired outcome in garment production. Factors such as fabric compatibility, weight, and the intended function of the garment play a significant role in this decision-making process. For instance, lighter interlinings are suitable for delicate fabrics, whereas heavier interlinings may be chosen for more robust clothing items. Additionally, the method of application—whether fusible or sew-in—will also influence the selection, based on the production capabilities and requirements.

Environmental Considerations and Sustainability

In recent years, the focus on environmental sustainability has led to the development of eco-friendly interlining options. These sustainable interlining rolls are made from recycled materials or organic fibers, catering to the growing demand for green alternatives in the textile industry. The adoption of such materials reflects a commitment to reducing the environmental footprint of garment production while still providing the necessary functionality of traditional interlinings.