Popular in your industry

Related Searches:

Top categories

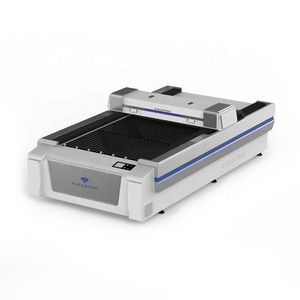

About laser cutting machine jewellery

A jewelry cutting machine is a machine utilized to create precise and intricate cuts on various jewelry materials. It is a specialized tool used by professional jewelers and artisans to craft jewelry pieces with intricate designs. This machine employs advanced laser technology to deliver accurate cuts, making it an essential device in the jewelry-making process.

What is a laser cutting machine for jewelry?

A laser cutter for jewelry is a highly versatile device that can cut through materials like gold, silver, and other precious metals with unparalleled precision. This machine uses a focused laser beam to melt, vaporize, or burn through the material, creating intricate and detailed cuts. It is particularly advantageous in the jewelry industry, where precision and fine detail are paramount.

How does a laser cutting machine for jewelry work?

A jewelry laser cutting machine works by harnessing the power of a highly concentrated laser beam to cut through various materials with exceptional precision. The process begins with the generation of the laser beam, typically produced by a CO2 laser or a fiber laser. The beam is then guided through a series of mirrors and lenses to focus it into a concentrated point.

Once the laser beam is focused, the jewelry piece is positioned on the machine's worktable. The operator uses computer-aided design (CAD) software to create the desired cutting pattern, which is then translated into digital instructions for the laser cutter. As the cutting process begins, the focused laser beam is directed onto the surface of the jewelry material, where it rapidly heats and vaporizes or burns away the material along the designated cutting path.

The speed and intensity of the laser beam can be precisely controlled, allowing for intricate designs and fine details to be achieved. The process is carried out in a controlled environment, often with the assistance of a gas, such as nitrogen or oxygen, to aid in the cutting process and prevent material residue. Once the cutting is complete, the jewelry piece is carefully removed from the machine, revealing clean, precise cuts.

Advantages of laser cutting machines for jewelry

Laser cutting machines offer several advantages, making them indispensable tools in the jewelry-making process. Firstly, their ability to deliver precise, intricate, and complex cuts is unparalleled. This precision allows artisans to create elaborate designs with fine details, giving their jewelry pieces a distinctive and high-quality finish.

Secondly, laser cutting machines are versatile and can be used on a wide range of jewelry materials, including precious metals like gold and silver, as well as gemstones and acrylics. Their adaptability makes them an ideal choice for cutting diverse materials, providing jewelers with the flexibility to explore creative designs.

Moreover, laser cutting is a non-contact process, meaning the laser beam does not physically touch the material during cutting. This non-invasive method reduces the risk of material distortion, ensuring minimal waste and preserving the integrity of the jewelry piece. Additionally, the speed and efficiency of laser cutting machines contribute to increased productivity in the jewelry-making process, allowing for quick turnaround times without compromising on quality.