Introduction to LED SMT Lines

Surface Mount Technology (SMT) lines are integral to the fabrication of modern electronics, including LED lighting systems, electronic motherboards, and various household devices. An LED SMT line is a collection of sophisticated machinery designed to streamline the production of electronic components with precision and efficiency. This introduction delves into the composition and functionality of these systems, offering insights into their applications and features.

Components of an LED SMT Line

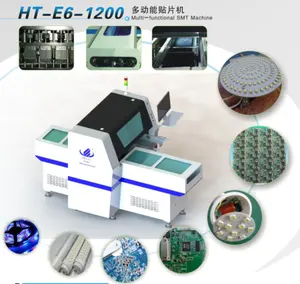

At the heart of an LED SMT assembly line are several key components, each serving a specific function in the production process. From PCB assembly machines that handle the initial stages of circuit board creation to advanced pick and place machines capable of placing thousands of microchips per hour, these lines are the backbone of electronic manufacturing. Soldering units within the line come equipped with adjustable settings to accommodate various PCB sizes and complexities, ensuring versatility across different projects.

Features and Applications

The LED SMT production line boasts a range of features designed to enhance the manufacturing process. A flux system is crucial for maintaining the integrity of the metals during soldering, preventing oxidation and ensuring clean connections. Meanwhile, the transport system within the line ensures seamless movement of PCBs through each production stage. Control interfaces are central to the operation, allowing technicians to adjust settings like temperature and conveyor speed for optimal performance.

Advantages of Using LED SMT Lines

Utilizing an LED SMT processing line brings numerous advantages to electronics production. The automation of these systems allows for high-volume output in reduced timeframes, a critical factor in meeting the demands of the fast-paced electronics market. Additionally, the precision of SMT lines minimizes errors, resulting in consistent product quality and reliability.

Materials and Technology

An LED SMT machine line is not only about the machinery but also about the advanced materials and technology that go into its construction. High-grade metals and composites ensure durability and longevity, while cutting-edge software enables intricate control over the entire production process. This combination of robust materials and technology results in a line that can withstand the rigors of continuous operation.

Choosing the Right LED SMT Line

Selecting the appropriate LED SMT equipment line is crucial for any business in the field of electronics manufacturing. Factors such as production capacity, machine speed, and the ability to handle different PCB sizes are essential considerations. Prospective buyers should assess their needs carefully to find a line that aligns with their production requirements and goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4