Popular in your industry

Related Searches:

Top categories

About mitsubishi injection moulding machine

Mitsubishi Injection Moulding Machine Overview

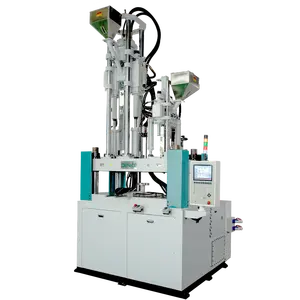

The Mitsubishi injection moulding machine stands as a cornerstone in the realm of industrial manufacturing, offering a robust solution for precision plastic part production. These machines are engineered for longevity and consistent performance, catering to a broad spectrum of industries that require meticulous molding capabilities.

Design and Applications

Each mitsubishi injection molding machine is a testament to ongoing design enhancements, ensuring compatibility with high-speed operations. These machines are not limited to a single industry but are versatile enough to serve sectors ranging from consumer electronics to automotive manufacturing. The adaptability of these molders means they are adept at producing a variety of components, including intricate pharmaceutical devices and durable automotive parts.

Technical Features

The technical prowess of the mitsubishi injection moulding machine is evident in its single-cylinder system equipped with a servo-valve, optimizing the response rate to meet industry standards. The specialized screw design enhances plasticizing capacity, improving both shot weight and speed. With clamping forces that range significantly, these machines are built to withstand the rigors of external machining forces, making them a reliable asset in the production of packaging materials, PVC pipe fittings, and more.

Material and Durability

Durability is a hallmark of the mitsubishi injection molding equipment, with each unit boasting a construction that promises a long service life. The materials used, particularly in the clamping unit's steel bush, are selected to minimize wear resistance and lubrication effects, which in turn can lead to cost savings in maintenance.

Accuracy and Precision

Precision is paramount in injection molding, and the mitsubishi injection moulding machine delivers on this front. The machines take plastic granules and mold them into precise dimensions required for various applications. This level of accuracy ensures that each product meets the stringent specifications demanded by the industry.

Environmental Considerations

In an era where environmental considerations are increasingly important, the mitsubishi injection moulding machine is designed to be efficient in its operation, potentially reducing waste and energy consumption. This efficiency is not only beneficial for the environment but also for the operators who seek to optimize their production processes.