Popular in your industry

Related Searches:

Top categories

About mould cutting machine

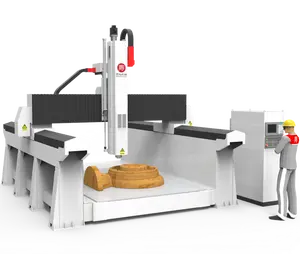

Introduction to Mould Cutting Machines

Mould cutting machines are precision tools used in various industries for cutting and shaping molds with high accuracy and efficiency. These machines are crucial for manufacturers involved in producing a wide range of products, including plastic items, metal parts, and even woodworking projects. The versatility and precision of mould cutting machines make them indispensable in modern manufacturing processes.

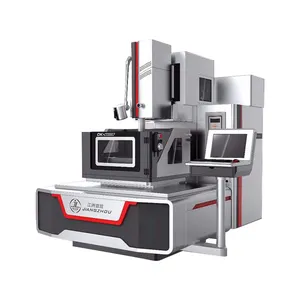

Types of Mould Cutting Machines

There are several types of mould cutting machines available in the market, each designed for specific applications. Some machines are specialized for cutting plastic molds, while others are suitable for metal or wood. Additionally, there are CNC-controlled mould cutting machines that offer automated precision cutting for complex shapes and designs. The choice of machine depends on the material being used and the intricacy of the molds.

Technical Specifications and Features

When selecting a mould cutting machine, it is essential to consider the technical specifications to ensure it meets the production requirements. Key features to look for include cutting speed, cutting depth, material compatibility, and precision level. The power capability of the machine, expressed in horsepower (hp), determines its cutting efficiency and performance. Additionally, the cutting blade type and size play a crucial role in achieving accurate and clean cuts.

Advantages of Using Mould Cutting Machines

The use of mould cutting machines offers numerous advantages to manufacturers. These machines enable faster production cycles, resulting in increased output and efficiency. The precision cutting capabilities of mould cutting machines ensure consistent quality in the manufactured products, reducing waste and rework. Moreover, by automating the cutting process, manufacturers can achieve higher levels of accuracy and repeatability in their molds.

Applications and Industries

Mould cutting machines find applications across various industries, including automotive, electronics, packaging, and furniture. In the automotive sector, these machines are used to produce precision parts and components for vehicles. In the electronics industry, mould cutting machines aid in the fabrication of intricate molds for electronic devices. The packaging industry benefits from the use of these machines to create custom molds for packaging materials.

Choosing the Right Mould Cutting Machine

When selecting a mould cutting machine for your business, consider factors such as the type of materials you work with, the complexity of the molds you need to create, and the production volume. It is essential to choose a machine that offers the necessary precision and speed to meet your production requirements. Additionally, ensure that the machine is easy to operate and maintain to maximize productivity.

Technical Support and Maintenance

Proper maintenance of mould cutting machines is crucial to ensure their optimal performance and longevity. Regular cleaning and lubrication of the machine components help prevent wear and tear. It is also essential to follow the manufacturer's guidelines for maintenance and servicing to avoid breakdowns and ensure consistent cutting quality. In case of any technical issues, having access to reliable technical support is essential for timely resolution.

Enhancing Efficiency with Mould Cutting Machines

By investing in high-quality mould cutting machines, businesses can enhance their production efficiency and competitiveness in the market. These machines streamline the manufacturing process, leading to cost savings and improved product quality. With advancements in technology, modern mould cutting machines offer innovative features that further enhance precision and speed, making them indispensable tools for manufacturers.

Future Trends in Mould Cutting Technology

The future of mould cutting machines lies in the integration of advanced technologies such as AI and IoT to enable predictive maintenance and real-time monitoring. Manufacturers are increasingly focusing on developing smart mould cutting machines that can optimize cutting processes and minimize downtime. By harnessing the power of data analytics and automation, the next generation of mould cutting machines will revolutionize the manufacturing industry.

Conclusion

In conclusion, mould cutting machines play a crucial role in modern manufacturing processes by enabling precision cutting of molds for various industries. By understanding the technical specifications, advantages, and applications of these machines, businesses can make informed decisions when investing in mould cutting technology. With continuous advancements in machine design and technology, the future looks promising for the evolution of mould cutting machines in enhancing production efficiency and quality.