Popular in your industry

Related Searches:

Top categories

About pfa injection molding parts

PFA Injection Molding Parts Overview

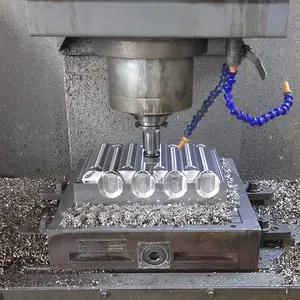

Injection molding is a versatile manufacturing process used for producing pfa injection molding parts from thermoplastic and thermosetting plastic materials. This technique is pivotal in creating parts with complex shapes and high precision, making it a cornerstone in industrial manufacturing. PFA, or perfluoroalkoxy, is a type of fluoropolymer with properties that make it ideal for use in various applications where high chemical resistance and thermal stability are required.

Types and Applications

The types of pfa injection molded components vary widely, catering to numerous sectors such as the automotive, medical, and electronics industries. These parts are integral to systems requiring excellent electrical insulation, or where harsh chemicals are present. Applications range from semiconductor parts, to chemical processing equipment, and even in the aerospace industry for its resistance to extreme temperatures and environments.

Material and Features

PFA materials are known for their robustness, able to withstand a wide range of temperatures and resist corrosion. The features of pfa plastic injection molding parts include non-stick characteristics and a high purity level, which is essential for applications in pharmaceuticals and food processing. These features ensure that the parts can perform reliably in demanding operational conditions.

Advantages of PFA Molding

The advantages of using pfa for injection molding are numerous. Its ability to create parts that maintain structural integrity under stress and high temperatures is unparalleled. Additionally, the versatility in design allows for the production of custom injection molding parts tailored to specific requirements, enhancing the efficiency of the manufacturing process.

Choosing the Right PFA Molding Parts

Selecting the appropriate pfa injection molding supplies involves considering the intended application, the environmental conditions the part will face, and the mechanical requirements. It is crucial to work with suppliers who can provide a range of options and who understand the intricacies of PFA material to ensure the final product meets the necessary specifications.

Streamlining Production with PFA Molding

Manufacturers can optimize their production by standardizing certain aspects of their pfa injection molds. This standardization can lead to cost savings and increased compatibility across various parts and systems. It is essential to collaborate with suppliers who can assist in refining the mold design for consistent quality and performance of the final parts.