Understanding Plastic Mold Packaging

Plastic mold packaging is a versatile and efficient solution for protecting and presenting a wide array of products. This category encompasses various types of packaging, including injection molded packaging and blow mold packaging, each with unique features suitable for different applications. The process involves shaping plastic materials into a desired form through a precise and controlled method, ensuring consistency and durability in packaging.

Types and Applications of Plastic Mold Packaging

The realm of plastic mold packaging is diverse, with options like molded plastic containers and injection molded plastic containers serving as prime examples. These containers are used in industries ranging from food and beverage to cosmetics, highlighting their adaptability. The selection of the type often depends on the specific requirements of the product, such as size, shape, and protection needs.

Materials and Features

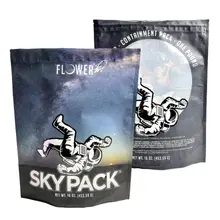

Materials such as PS (polystyrene), PE (polyethylene), and POM (polyoxymethylene) are commonly used in the production of plastic mold packaging. These materials are chosen for their strength, flexibility, and ability to preserve the contents. Features like embossing and glossy lamination can be applied to enhance the aesthetic appeal and tactile experience, making the packaging not just functional but also visually attractive.

Advantages of Plastic Mold Packaging

The advantages of using plastic mould packaging are numerous. It offers excellent protection for the contents, maintaining their integrity during transport and storage. Additionally, the lightweight nature of plastic reduces shipping costs, while the ability to recycle many plastic packaging types aligns with eco-friendly practices. Moreover, the customization potential of plastic mold packaging allows for a tailored approach to meet specific product needs.

Innovations in Plastic Mold Packaging

Innovation in the field has led to the development of moulded polystyrene packaging, which provides superior insulation properties, making it ideal for temperature-sensitive products. Companies like Mold Tek Plastics Ltd are at the forefront of these advancements, offering specialized packaging solutions that cater to a broad spectrum of market requirements.

Choosing the Right Plastic Mold Packaging Supplier

Selecting the appropriate supplier for plastic mold packaging is crucial. It involves evaluating the supplier's capability to provide the right type of packaging, such as injection molded plastic packaging, that meets the product's protection and presentation needs. While Alibaba.com does not endorse any specific suppliers, the platform facilitates connections between buyers and a diverse range of experienced suppliers in the plastic mold packaging industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4