Popular in your industry

Related Searches:

Top categories

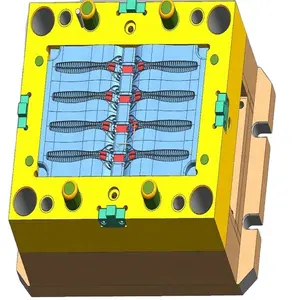

About plastic mould blade razor

Introduction to Plastic Mould Blade Razors

Plastic mould blade razors are integral components in the manufacturing sector, designed for precision cutting with a focus on durability and efficiency. These specialized blades are crafted through meticulous injection molding processes, ensuring consistent quality and performance. The application of these blades spans across various industries, from personal care to professional-grade equipment.

Types and Applications

The versatility of plastic mould blade razors is evident in their diverse types, each tailored for specific applications. From intricate designs for personal grooming products to robust versions for industrial use, these blades are essential for tasks requiring sharp, accurate cuts. Their usage extends to packaging, medical devices, and other specialized equipment, highlighting their importance in daily operations and product development.

Material and Features

Selecting the appropriate material for a plastic mould blade razor is crucial for its functionality. Options range from high-grade metals to advanced polymers, each offering unique characteristics such as corrosion resistance and longevity. Features like edge retention and ergonomic design are also critical, ensuring that the blades meet the rigorous demands of their intended use.

Advantages of Injection Molding

Injection molding presents several advantages for producing plastic mould blade razors. This method allows for high precision in mass production, maintaining uniformity across batches. It also offers flexibility in design, enabling the creation of complex shapes that would be challenging to achieve through traditional manufacturing methods. Moreover, injection molding is cost-effective at scale, making it a preferred choice for businesses looking to optimize their production line.

Customization and Standardization

Customization is a key aspect of creating a plastic mould blade razor, with the process allowing for adjustments in design to meet specific requirements. Conversely, standardization of certain mold elements can streamline production and reduce costs. Implementing uniform features such as lift bars, connection sizes, and clamp slots can simplify the manufacturing process, especially when producing multiple products that can share these standardized components.

Choosing the Right Supplier

Identifying a reliable supplier for plastic mould blade razors is essential. Prospective buyers should seek out suppliers who demonstrate expertise in mold design and fabrication, and who are willing to collaborate on test runs to ensure the mold meets the precise needs of the product. It is important to engage with suppliers who are responsive and provide the necessary information to make an informed decision.