Introduction

In the ever-evolving world of construction, materials once deemed ordinary are being repurposed in extraordinary ways. One such material is the humble plastic polythene sheet. Known for its versatility, polythene has found its way into modern construction, offering innovative solutions to age-old problems. This article delves into the properties of polythene, its types, and its innovative uses in construction. We will explore how this simple plastic sheeting is being used for everything from vapor retardation to weatherproofing, and even temporary structure protection. We will also discuss the benefits, limitations, and the environmental impact of using plastic polythene sheets in construction.

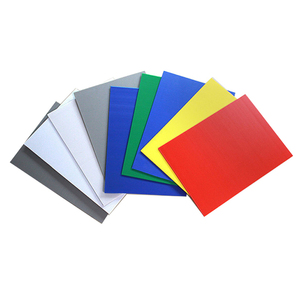

Understanding Plastic Polythene Sheets

Polyethylene, also known as Polythene, is a highly versatile plastic used in various applications, from heavy-duty damp proof membranes to light, flexible bags and films. Two major types are LDPE (Low Density) and HDPE (High Density). LDPE is used for trays and heavier duty films, while HDPE is used for thin gauge carrier bags, fresh produce bags, and some bottles and caps. By altering the formulation and gauge of polyethylene, manufacturers can adjust its properties such as impact and tear resistance, transparency, flexibility, and coating capability. Polyethylene also offers excellent moisture barrier qualities and is chemically inert.

Types of Plastic Polythene Sheets in Construction

Plastic polythene sheets, also known as polyethylene sheeting, vary in quality and application. The lowest grade, often termed 'construction grade,' is made from recycled goods and inexpensive resins. It's not guaranteed to be defect-free and lacks longevity. However, engineered films, made from 100% virgin resins, are designed specifically for use as vapor retarders under concrete slabs. These high-quality sheets are tested to ASTM E1745 standards, ensuring they don't decay easily and maintain structural integrity for longer periods.

Innovative Uses of Plastic Polythene Sheets

Plastic polythene sheets, particularly construction-grade ones, have found innovative uses in modern construction. They are often used as vapor retarders under concrete slabs, playing a crucial role in preventing moisture from seeping into the structure. They are also used under homes or in crawl spaces, depending on regional humidity levels and existing vapor retarders. Furthermore, these sheets can be used as barriers against radon or methane in areas where these gases are prevalent. However, it's important to note that not all plastic sheets are created equal, and their effectiveness can vary.

Weatherproofing and Insulation

Plastic sheeting is a heavy-duty coverall that can be used as a moisture and vapor barrier, insulation and a paint drop cloth for floors. This sheeting can cover up to 1,200 sq. ft. and is clear. Used as a dropcloth or spray barrier, a vapor barrier in interior walls or in crawl spaces, primarily used as a barrier in the drywall trade, and used as a cover possibly for curing with concrete.

Temporary Structures and Protection

Polythene sheeting serves as a temporary protective material in construction. It can be used as a dust cover, safeguarding floors during painting or large, immovable furniture during works. Moreover, it can temporarily seal buildings under construction, protecting them from light winds and rain, especially during unexpected delays. This versatile material ensures the continuity of construction activities, even when full installation of doors, windows, or roofing elements is pending.

Vapor and Moisture Barriers

Plastic polythene sheets play a crucial role as vapor and moisture barriers, especially in construction. However, not all sheets are created equal. The lowest grade, often used in construction, can have defects and lacks longevity. Experts recommend engineered films designed specifically for use as vapor retarders. These are made from 100% virgin resins and are tested to high standards. They are engineered not to decay, unlike most construction grade poly, which can lose structural integrity within 2 years. The choice of vapor retarder can significantly impact the longevity and quality of hardwood flooring.

Benefits and Limitations of Plastic Polythene Sheets in Construction

Plastic polythene sheets, particularly construction-grade ones, have their benefits and limitations. They are often used as vapor retarders in construction, preventing moisture from seeping into structures. However, their quality varies significantly. Lower-grade sheets, made from recycled goods and inexpensive resins, may have defects and lack longevity. High-quality vapor retarders, made from 100% virgin resins, are engineered to withstand decay and maintain structural integrity for longer. They are also capable of retarding harmful gases like radon and methane. However, the wrong choice of product can lead to issues like buckling, warping, and noisy flooring.

Environmental Impact and Sustainability of Plastic Polythene Sheets

Plastics in construction, including plastic polythene sheets, are energy and resource-efficient, providing quality performance over a long lifespan. They help keep buildings dry and warm, ensuring comfortable living and working spaces, while being cost-effective. Plastic materials can last longer than other materials, reducing the need for new products. They can also be reused, recycled, or recovered at the end of their service life, contributing to a circular economy. The energy saved across the lifetime of plastics used in construction outweighs the energy used in their manufacturing.

Conclusion

In conclusion, plastic polythene sheets have proven to be a versatile and innovative material in modern construction. Their use as vapor retarders, weatherproofing agents, and temporary structure protectors, among other applications, has significantly enhanced the efficiency and sustainability of construction practices. However, it's crucial to choose high-quality sheets, as the quality can significantly impact the longevity and performance of the construction. Despite some limitations, the benefits of plastic polythene sheets, particularly their contribution to a circular economy and their long lifespan, make them a valuable asset in the construction industry. As we continue to strive for sustainable and efficient construction practices, the innovative use of materials like plastic polythene sheets will undoubtedly play a pivotal role.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4