Introduction to Pneumatic Round Hole Punches

Pneumatic round hole punches are essential tools in the realm of material processing, offering a blend of efficiency and precision for creating round holes in various sheet materials. These devices leverage compressed air to exert force, making them a staple in environments ranging from industrial assembly lines to smaller workshops and even for the avid DIY enthusiast.

Types and Applications

The versatility of pneumatic round hole punches is evident in their wide range of types and applications. From hydraulic to manual and CNC-operated units, each variant serves a specific purpose. Hydraulic punches cater to heavy-duty operations, while manual punches suit occasional tasks. CNC punches excel in complex, repetitive tasks, highlighting their use in continuous mass production.

Features and Materials

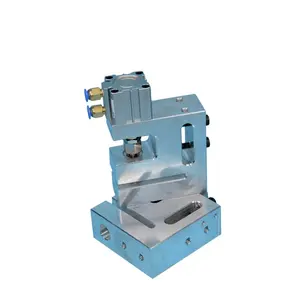

A pneumatic round hole punch is characterized by its ability to handle various materials with precision. Whether it's for punching through metal, plastic, or paper, these machines are designed to deliver clean and consistent holes. Materials like hardened steel and high-grade aluminum are commonly used in their construction, ensuring durability and long-term performance.

Advantages of Pneumatic Punching Machines

The main advantage of using a pneumatic round hole punch lies in its efficiency and accuracy. Pneumatic systems reduce manual labor and increase the speed of production. Additionally, some models are equipped with servo drives, enhancing their precision, which is particularly beneficial for sectors requiring meticulous work, such as medical tool manufacturing.

Selecting the Right Punch

Choosing the appropriate pneumatic round hole punch involves considering factors such as material compatibility, production rate, and automation features. Prospective buyers can filter through an array of options to find a punch that aligns with their operational needs, ensuring that their investment is tailored to their specific requirements.

Conclusion

In conclusion, a pneumatic round hole punch is a valuable addition to any material processing setup. With a variety of types available to suit different applications and features designed for optimal performance, these tools are indispensable for businesses looking to enhance their production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4