Popular in your industry

Related Searches:

Top categories

About powder mixer 10 kg

What is 10 Kg Powder Mixer

A 10 kg powder mixer is an essential industrial machine designed for blending dry ingredients into a homogeneous and fine-grained mixture. This equipment is instrumental in various sectors, including pharmaceuticals, food processing, and chemical industries. It is particularly useful for businesses that require consistent product quality and for processes that involve blending large volumes of powders.

The principle behind a powder mixer is simple yet effective: it uses a rotating mechanism to combine the ingredients. The mixer's container, often resembling a drum or a trough, is set in motion by an electric motor. This motion can be either horizontal or vertical, depending on the design of the machine and the requirements of the materials being mixed.

These mixers are equipped with features that ensure efficiency and safety. They typically have airtight seals to prevent dust from escaping, ensuring a clean working environment and protecting workers from potential health hazards associated with inhalation of fine particles. The design and materials used are often chosen for their durability and ease of cleaning, with options for stainless steel or other high-grade metals that meet strict hygiene standards.

The 10 kg powder mixer caters to the specific needs of businesses that handle dry ingredients on a large scale. Its capacity allows for mixing substantial batches, making it ideal for bulk production. The resulting mixture is consistent and well combined, which is crucial for achieving the desired texture, taste, and appearance in the final product.

Types of 10 kg Powder Mixer

In the marketplace of industrial machinery, there exists a diverse range of 10 kg powder mixers each tailored to specific applications:

-

Ribbon Mixer: This type is characterized by a long, narrow, and shallow trough with a central shaft that has a ribbon-like structure attached to it. It is commonly used for mixing fine powders and is known for its fast and efficient mixing capabilities.

-

Rotary Mixer: Also called a drum mixer, this variant features a cylindrical drum that rotates on its axis. It is ideal for mixing large quantities of heavy materials and is frequently used in the food processing industry.

-

Double Cone Blender: Offering a gentle mixing action, this mixer is suitable for blending cohesive materials. Its conical shape allows for a good circulation of the powder, which is excellent for mixing pharmaceuticals and other fine-grade applications.

-

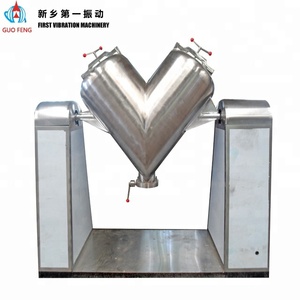

V-Mixer: With a v-shaped body and two opposite-moving agitators, this mixer type provides thorough mixing action that is especially effective for mixing sticky materials.

How to choose 10 Kg Powder Mixer

Selecting the right 10 kg powder mixer requires careful consideration of several factors relevant to your business needs. When choosing a mixer for commercial catering or food processing, it's important to consider the volume of material you need to mix regularly. A planetary mixer might be ideal for high-volume bakeries whereas a drum mixer could suffice for small-scale operations.

Next, think about the type of materials you'll be mixing. If you frequently work with thick pastes or doughs that require heavy-duty mixing, a robust mixer with high torque and durability would be essential. For lighter batters or meringues where aeration is key, a rotary whip mixer may be more appropriate.

Also, reflect on the available space within your facility. Floor space can dictate whether you opt for a freestanding model or one that can be placed on a countertop. Additionally, consider whether portability is important for your business model—models with wheels can offer greater flexibility in use across different areas of your establishment.

Lastly, examine the level of customization you require. Some mixers come with advanced control options like PLCs for automated programming or touch screens for more user-friendly interaction. If customization isn't crucial for your operation, you may find that an off-the-shelf model can meet your needs effectively.

About 10 Kg Powder Mixer on Alibaba.com

Alibaba.com stands out as an essential marketplace for businesses seeking reliable powder mixers designed to meet a range of industrial needs. The platform's extensive selection allows businesses to find the perfect solution regardless of their size or specific requirements. With local service locations across various countries including the Philippines, Russia, and Thailand, buyers can access machinery that's tailored to their local market's needs while benefiting from features such as order handling and delivery services provided by Alibaba.com.

The commitment to facilitating global trade is evident through Alibaba.com's user-friendly interface that supports multiple languages and mobile-friendly features. Businesses can easily communicate with suppliers, negotiate terms, and arrange for after-sales support through the platform's comprehensive services. Moreover, Alibaba.com's Trade Assurance service offers peace of mind by safeguarding payments until buyers confirm satisfactory delivery of their purchases.

By choosing Alibaba.com for sourcing powder mixers, businesses tap into a vast network of suppliers offering an array of options that cater to diverse applications – from food processing to pharmaceuticals and beyond. This variety ensures that no matter what industry you're in or what core components you require for your machinery, you'll find solutions that align with your operational needs while enjoying support at every step from an established and secure platform like Alibaba.com.

Common FAQs for 10 Kg Powder Mixer

What is the capacity range of powder mixers available for industrial use?

Powder mixers for industrial use come in various capacities, typically measured in kilograms, to accommodate different production scales and the volume of materials that need to be mixed.

How do I determine the right type of powder mixer for my business?

Consider the material you'll be mixing, as different powders may require different types of mixers. Ribbon mixers are suitable for blending materials with a consistent particle size; rotary mixers are ideal for mixing materials with larger variations in their composition.

Can powder mixers be used for liquid-based products?

Yes, some powder mixers are specifically designed to handle liquid ingredients, but they may not be suitable for all types of liquids. It's important to check the specifications of the mixer to ensure it meets your liquid-handling needs.

What safety features should I look for in a powder mixer?

Look for features like emergency stop buttons, overcurrent protection, and safety guards that can help prevent accidents and ensure safe operation in your facility.

Are there powder mixers suitable for cleanroom environments?

Yes, there are powder mixers designed with cleanroom environments in mind, featuring smooth surfaces and easy-to-clean designs to prevent contamination.

What materials are powder mixers typically made from?

Powder mixers can be made from a variety of materials including 304 stainless steel, carbon steel, and sometimes more specialized materials based on the requirements of the mixing process.

How do I choose between a single-shaft and double-shaft powder mixer?

Single-shaft powder mixers are typically used for smaller batches and applications where easy access for cleaning is important. Double-shaft mixers are better suited for larger batches and applications where more thorough mixing is required.

Can powder mixers handle continuous operation?

Yes, some powder mixers are designed for continuous operation such as the fluidized bed type which can handle a continuous stream of material.

Is it possible to get a custom-designed powder mixer on Alibaba.com?

While Alibaba.com connects buyers with suppliers who may offer customization options, it is advisable to communicate directly with suppliers to discuss specific customization requirements for your powder mixer.

What additional capabilities can powder mixers have?

Additional capabilities may include drying or milling functions that can be integrated into the powder mixing process to enhance efficiency and meet specific application needs.

How does Alibaba.com ensure the quality of the powder mixers listed on its platform?

Alibaba.com provides tools like supplier ratings and customer service assistance to help buyers make informed decisions about the quality of the powder mixers available on its platform.