What are Precast Wall Cost Estimation

Precast wall cost estimation is a critical step in planning and budgeting for construction projects. Precast walls are structural elements that are manufactured off-site and then transported and installed at the construction site. This method of construction is becoming increasingly popular due to its many advantages, including speed of installation, high quality control, and reduced labor costs. The estimation process considers various factors such as the type of precast wall, size, design complexity, and site-specific requirements to determine an accurate cost projection.

The primary users of precast wall cost estimation are construction companies, developers, architects, and project managers who are involved in building projects. By providing an estimate, they can make informed decisions regarding the feasibility of a project, allocate resources effectively, and ensure that the construction meets budgetary constraints without compromising on the quality of the final product.

The estimation is based on the principles of precasting, where concrete is cast into a reusable mold, cured off-site, and then transported to the construction site. This method allows for consistent quality and can significantly reduce construction time. The cost estimation takes into account the materials, manufacturing process, transportation, and any additional services required for the installation such as site preparation or foundation work.

Types of Precast Wall Cost Estimation

The cost estimation of precast walls varies based on the type of wall, its design complexity, and the materials used. Here are some common types:

-

Retaining Wall: These walls are utilized to retain soil and other materials. They are often seen in landscaping projects to create level terraces or in industrial settings to support vertical loads.

-

Boundary Wall: A precast wall that serves as a boundary for a property. It's typically installed around homes, factories, or farms to provide privacy or security.

-

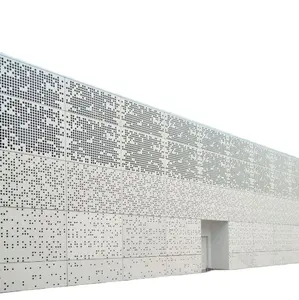

Sound Barrier Wall: Designed to reduce noise from traffic or industrial activities. They are frequently used along highways or near residential areas to mitigate noise pollution.

-

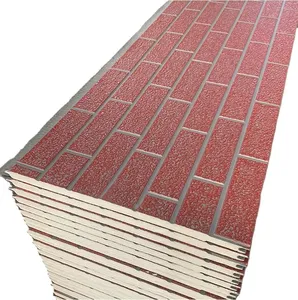

Decorative Wall: These come in various finishes and are employed purely for aesthetic purposes. They can be used in residential or commercial environments to enhance the visual appeal of a space.

-

Load-Bearing Wall: Precast walls that are designed to carry structural loads. They are found in buildings such as warehouses, schools, and hospitals where heavy-duty walls are needed.

How to choose Precast Wall Cost Estimation

Selecting the right precast wall system requires careful consideration of several factors:

-

Design Requirements: The specific design needs will heavily influence the choice of precast wall system. For instance, if a project calls for intricate designs with unique shapes or complex architectural features, a standard panel system may not suffice. In such cases, a more flexible system like 3D concrete elements or customized panels might be necessary.

-

Structural Needs: The intended application will determine whether a load-bearing system or a cladding system is more appropriate. For example, hollow core panels may be better suited for structural support while solid panels may be better for decorative purposes.

-

Site Conditions: Factors such as soil stability, water table levels, and environmental exposure should be evaluated to determine the most suitable precast wall system. For instance, sandwich panels may be required for areas with high water tables to prevent seepage issues.

-

Installation Process: The chosen system should align with the available resources for installation, including labor and machinery. Some systems may require heavy machinery or specialized installation techniques which could impact the overall project schedule.

-

Maintenance and Durability: Consideration should be given to long-term maintenance needs and the expected lifespan of different wall systems. Additionally, some systems may offer energy-saving properties which can provide cost benefits over time.

Businesses looking to purchase precast wall systems through Alibaba.com's B2B marketplace can filter options based on these functional requirements as well as supplier capabilities such as local service location or after-sales support provided.

About Precast Wall Cost Estimation on Alibaba.com

Alibaba.com stands out as a global marketplace that connects businesses with a vast selection of precast walls suitable for diverse construction needs. This platform offers an extensive range of options from numerous suppliers around the world, ensuring businesses can find exactly what they need for their specific project requirements. Alibaba.com simplifies international trade by providing tools and services that facilitate easy communication between buyers and suppliers regardless of language barriers or geographical distances.

The variety of precast walls available on Alibaba.com includes options suitable for different industries such as hotels, villas, retail spaces, and many more. With detailed product descriptions and supplier information, businesses can make informed decisions that align with their project goals in terms of cost, design complexity, and construction efficiency. Alibaba.com's Trade Assurance service adds an extra layer of security to transactions, ensuring payments are protected until delivery is completed.

Choosing Alibaba.com as your sourcing platform means accessing a wealth of products from certified suppliers who meet global quality standards. Whether your project requires insulated panels for energy efficiency or fire-resistant walls for safety precautions, Alibaba.com offers a streamlined solution for procuring high-quality precast walls on a wholesale level. This commitment to facilitating easy business transactions makes Alibaba.com an indispensable resource for companies seeking to optimize their procurement process while ensuring they receive materials that meet their professional standards.

Common FAQs for Precast Wall Cost Estimation

What are the main advantages of using precast wall panels over traditional construction methods?

Precast wall panels offer several advantages over traditional construction methods including reduced construction times, consistent quality due to factory production, and the ability to withstand extreme weather conditions.

How do the costs of precast wall panels compare to traditional construction methods?

Precast wall panels can offer significant cost savings in terms of material and labor due to their efficient production and faster installation. The level of savings will vary depending on the complexity of the design and the quantity of panels needed.

Can precast wall panels be customized to fit specific design requirements?

Yes, precast wall panels can be customized to fit the specific dimensions, shapes, and design elements required for your project. Suppliers on Alibaba.com can work with you to meet these customizations.

What types of core materials are available for precast wall panels?

Core materials commonly used in precast wall panels include materials like expanded polystyrene (EPS), extruded polystyrene (XPS), or polyurethane. The choice of core material affects the panel's thermal insulation properties and overall cost.

How does the installation process of precast wall panels compare to traditional construction methods?

Installing precast wall panels is typically faster and requires less on-site labor. Panels are manufactured off-site, allowing for quick placement and minimal on-site work.

Are there any limitations to using precast wall panels in construction?

Precast wall panels are highly versatile but may have limitations in terms of transportation size and the need for on-site handling equipment. It's important to assess site conditions and logistics before choosing this construction technique.

How do I determine the right thickness for precast wall panels?

The thickness of precast wall panels should be chosen based on the structural requirements of your project. Suppliers can provide guidance on the appropriate thickness based on load-bearing calculations and local building codes.

Can precast wall panels be used for both interior and exterior walls?

Yes, precast wall panels are suitable for both interior and exterior walls. The choice of panel should be based on the intended application and the specific environmental conditions of the installation site.

What is the typical lifespan of precast wall panels?

Precast wall panels can have a lifespan of several decades when properly maintained. The durability of these panels varies based on material quality and environmental factors.

How do I know if a supplier's precast wall panels will meet local building codes?

It is important to coordinate with local authorities to ensure that the panels comply with all relevant building codes and regulations before making a purchase.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4