Popular in your industry

Related Searches:

Top categories

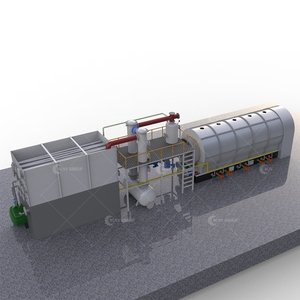

About pyrolysis machine

A pyrolysis machine is a specialized tool designed to thermally decompose organic materials in an environment with limited oxygen. This process, known as pyrolysis, involves subjecting the material to high temperatures in the absence of oxygen, leading to the breakdown of complex molecules into simpler compounds. The primary objective of a pyrolysis machine is to transform various feedstocks, such as plastic, tires, biomass, or rubber, into valuable end products like fuel, biochar, and syngas. The machine encompasses various components, including a reactor, heating system, condensation system, and emission control devices, all working together to facilitate the pyrolysis process.

Types of Pyrolysis Machines

There are different types of pyrolysis machines based on the feedstock they process, such as plastic, rubber, biomass, and tires. For example, a plastic pyrolysis machine is specifically designed to handle plastic waste, while a biochar pyrolysis machine focuses on converting biomass into biochar. The capacity of pyrolysis machines can also vary, ranging from small-scale, batch-type units to large, continuous pyrolysis plants capable of processing tons of feedstock per day.

Applications and Benefits of Pyrolysis Machines

Pyrolysis machines play a crucial role in waste management and resource recovery by converting various organic materials into valuable products. The applications of pyrolysis machines are diverse and include waste-to-energy processes, biochar production for soil improvement, and the generation of valuable chemicals from biomass. Given the growing concern for environmental sustainability, these machines offer an eco-friendly solution to deal with organic waste. The benefits of a pyrolysis machine are vast and include efficient resource utilization, reduced environmental impact, and the potential for generating renewable energy. Moreover, the versatility of pyrolysis machines enables them to contribute to the circular economy by closing the loop on waste streams and creating a sustainable approach to material management.

Factors Determining the Cost of a Pyrolysis Machine

Several factors influence the cost of a plastic pyrolysis machine. The machine's size and processing capacity are significant determinants, as larger and more robust units typically come with a higher price tag. The technology and features integrated into the machine also play a crucial role. More advanced pyrolysis machines with sophisticated control systems, better energy efficiency, and enhanced safety features can be more expensive. Additionally, the choice of materials and components used in the construction of the machine impacts its overall cost. Furthermore, logistical considerations, such as shipping and installation, contribute to the total expense. Market dynamics, including the availability of raw materials, regulatory requirements, and the competitive landscape, can also influence the plastic pyrolysis plant cost. It is essential for buyers to evaluate their specific needs, compare different options, and consider the long-term operational costs in addition to the initial pyrolysis machine price to make an informed investment decision.