Popular in your industry

Related Searches:

Top categories

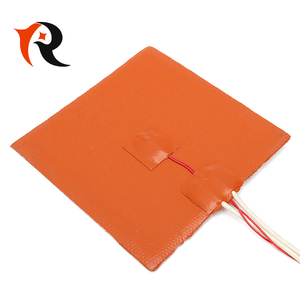

About silicone rubber heater

Introduction to Silicone Rubber Heaters

Silicone rubber heaters are versatile and efficient thermal solutions designed to provide reliable heat across a wide range of applications. These flexible heaters are constructed from high-strength silicone rubber which inherently provides excellent thermal properties. They are engineered to offer uniform heat distribution and rapid thermal response, ensuring that heat is delivered precisely where it is needed.

Types and Configurations

There are various types of silicone rubber heaters, including wire-wound and etched foil designs. The wire-wound type is known for its durability, while the etched foil variant provides superior heat distribution and faster warm-up times. These heaters can be customized in numerous shapes, sizes, and wattages, catering to a multitude of industrial and commercial applications.

Applications and Uses

The application of silicone rubber heating elements spans across industries from aerospace to food service. They are commonly used for tank and drum heating, anti-condensation in electronics, and as components in medical devices. Their flexibility allows them to be fitted to various surfaces, including curved and irregular shapes, making them an adaptable solution for complex heating requirements.

Features and Material Specifications

Flexible silicone heaters are known for their resilience and chemical resistance, which makes them suitable for harsh environments. The silicone material is moisture and chemical-resistant, ensuring longevity and consistent performance. Additionally, these heaters can be equipped with thermostats, sensors, and digital controllers to enhance precision in temperature management.

Advantages of Silicone Rubber Heating Solutions

The advantages of using silicone heaters are manifold. They provide efficient thermal transfer, are lightweight, and have a low thermal mass, which means they can heat up and cool down quickly. Their flexibility does not compromise their strength, as they are robust enough to withstand repeated flexing. Moreover, their thin profile allows for excellent heat transfer and quick thermal response.

Considerations for Selection

When selecting a silicone rubber heater, it is crucial to consider the application's specific requirements, such as temperature range, size, shape, and power density. It is also important to evaluate the environmental conditions the heater will be exposed to, such as moisture, chemicals, or mechanical stresses, to ensure optimal performance and longevity.