Exploring the Versatility of Slipper Molds

Slipper molds are a foundational tool in the manufacturing of footwear, serving a diverse range of applications from the creation of everyday household slippers to the production of specialized ballet shoes. These molds are essential for shaping the material into a comfortable and functional product.

Types and Materials of Slipper Molds

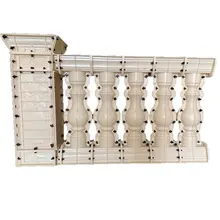

Slipper molds come in various materials, each selected for its properties and the specific requirements of the molding process. Iron molds are known for their durability and heat resistance, making them suitable for high-volume production runs. On the other hand, ballet shoe molds may utilize more specific materials that cater to the delicate design and requirements of ballet footwear. The choice of material impacts the mold's performance, longevity, and the quality of the final product.

Applications and Features

The application of slipper molds extends beyond the conventional. For instance, ballet slipper molds are intricately designed to capture the elegance and precision needed for ballet footwear. In contrast, ballet slipper chocolate molds are used in the culinary industry to create themed confectioneries. Each mold is crafted to ensure the accurate representation of the design, whether it's for wearing or for edible art.

Advantages of Precision Molding

Utilizing a precise slipper mold ensures that each product maintains consistency in shape and size, which is crucial for footwear comfort and performance. The adaptability of molds allows for the creation of various designs, including those of glass slipper molds, which are sought after for their intricate details and aesthetic appeal.

Customization and Standardization

Customization plays a pivotal role in mold selection. A ballet shoe mould can be tailored to specific design requirements, ensuring that the unique contours of ballet footwear are perfectly captured. Standardization of certain mold elements, such as lift bars and clamp slots, can be optimized to reduce production costs and increase compatibility across different molding machines.

Choosing the Right Mold for Your Needs

When selecting a slipper mold, it's important to consider the specific needs of your product. Whether you're in the market for a ballet shoe chocolate mold or a robust mold for daily slipper production, the vast selection available through Alibaba.com's network of suppliers ensures that you can find the right mold to meet your manufacturing requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4