Popular in your industry

Related Searches:

Top categories

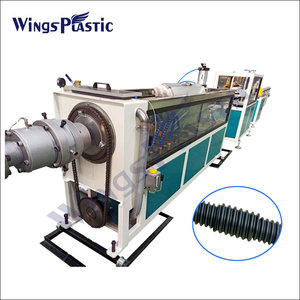

About spiral corrugated tube making machine

Introduction to Spiral Corrugated Tube Making Machines

Spiral corrugated tube making machines are specialized pieces of equipment designed for the production of corrugated tubes used in various industries. These machines are essential for creating durable and flexible tubing solutions that cater to a wide range of applications, from drainage systems to protective wiring conduits.

Types and Applications

The applications of spiral corrugated tube making machines are diverse, serving sectors such as construction, electrical, and automotive industries. The tubes produced are integral in safeguarding electrical wires, managing fluid transfer, and providing lightweight conduits for gases and liquids. The two primary types of machines used in the manufacturing process are single screw and twin screw extruders, each offering distinct advantages depending on the production requirements.

Machine Features and Capabilities

Modern spiral corrugated tube making machines boast features that enhance efficiency and precision. They come equipped with advanced control systems for regulating temperature, speed, and other critical parameters. The twin screw variants are particularly known for their high output rates and consistent product quality, making them suitable for large-scale production needs. Single screw machines, while simpler, provide a cost-effective solution for lower-volume manufacturing without compromising the integrity of the tubes produced.

Materials and Advantages

These machines are capable of processing a variety of plastic materials, including PVC, HDPE, and PP, which are chosen for their durability, flexibility, and resistance to chemicals. The advantage of using spiral corrugated tube making machines lies in their ability to recycle plastic materials, contributing to sustainable production practices. Additionally, the extrusion process is highly versatile, allowing for the creation of tubes with varying diameters, lengths, and wall thicknesses to meet specific industry standards.

Choosing the Right Machine

Selecting the appropriate spiral corrugated tube making machine involves considering factors such as material compatibility, production capacity, and the specific type of corrugated tubing required. It is crucial to assess the machine's output rate and ensure it aligns with the production demands. Furthermore, the decision between a single or twin screw machine will largely depend on the efficiency and volume requirements of the operation.

Conclusion

In conclusion, the spiral corrugated tube making machine is a pivotal investment for businesses looking to produce high-quality corrugated tubes. With the ability to handle various materials and produce tubes that meet diverse application needs, these machines are a cornerstone in the manufacturing of reliable and essential industrial products. Alibaba.com serves as a comprehensive source for businesses to find a range of these machines to suit their production specifications.