Exploring the Versatility of Wire Bending Machines

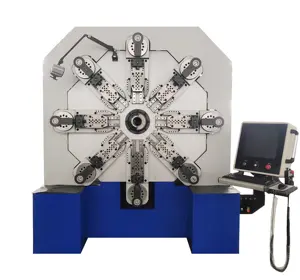

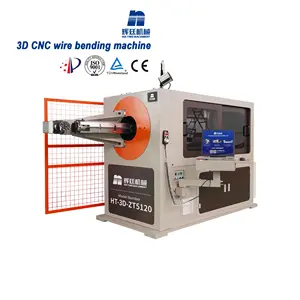

The realm of metal fabrication is incomplete without the mention of wire bending machines. These machines are pivotal in shaping wires into various configurations for a multitude of applications. Among the diverse types available, the used CNC wire bender stands out for its precision and programmability, catering to intricate design requirements.

Types of Wire Bending Machines

Understanding the different machines is crucial for selecting the appropriate one for specific tasks. The rotary draw bending machine is known for its precision, utilizing a clamping mechanism and a rotating bend die to shape the tube. Roll benders, on the other hand, employ a trio of rollers to achieve the desired curve, with the upper roller's height being adjustable. The vector wire bending machine used mirrors the rotary draw's functionality but is distinguished by its vector-based movements, allowing for complex bends.

Components and Functionality

The efficacy of a wire bending machine used is largely due to its components. The bend die is central to the operation, dictating the internal radius of the bend. The clamp die secures the tube to the bend die, preventing slippage during the process. To ensure the tube conforms to the bend die's path, the pressure die applies the necessary force. The wiper die is integral in maintaining the smoothness of the bend's interior by mitigating wrinkles. Lastly, the mandrel is a critical support feature, preventing the tube from collapsing during the bending process.

Applications and Advantages

Wire bending machines are indispensable in various industries, from automotive to aerospace, where precise metal shapes are required. The use of a used wire bending machine can be particularly cost-effective while still providing the necessary functionality for detailed work. The adaptability of these machines allows for a wide range of applications, from simple hooks to complex automotive parts.

Choosing a used CNC wire bender from Alibaba.com's extensive collection means accessing a machine that can deliver intricate bends with repeatability and precision. The platform's collaboration with numerous suppliers ensures a diverse selection to meet different operational needs without compromising on the machine's capabilities.

Material Considerations and Features

When selecting a wire bending machine used, it's important to consider the type of material it can handle. Machines vary in capacity, with some designed for light wires and others capable of bending thicker, more robust materials. Features such as multi-axis bending, programmable logic controllers, and quick-change tooling contribute to the machine's flexibility and efficiency.

In conclusion, Alibaba.com offers a gateway to a vast array of used wire bending machines, each with its own set of features and capabilities. While the platform facilitates the connection between buyers and suppliers, it is the buyer's responsibility to ensure the chosen machine meets their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4